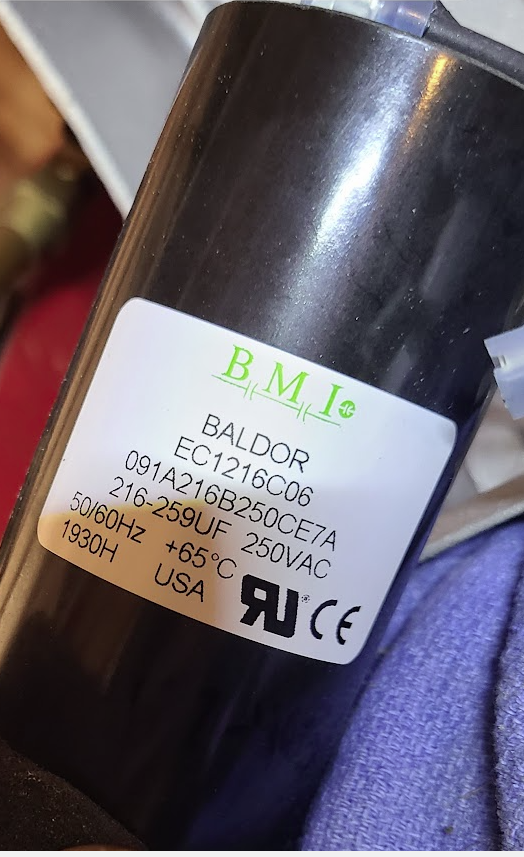

Hi all, first I am not an electronics guys so sorry if I have any errors in what I am trying to explain. I have a single phase 220v air compressor that has 3 capacitors. Two are start and one is the run. I am using a clamp on meter that has a capacitor setting to check each one (klein cl-800). 2 out of the 3 tested within spec of the uf range on the label. The third however, has 2 resistors soldered onto the terminals. This one is the same as the other start capacitor, expect for the soldered resistors. When I check it with the probes, its out of spec. But I am thinking that the resistors are throwing those numbers off and wanted to sk if that was the case?

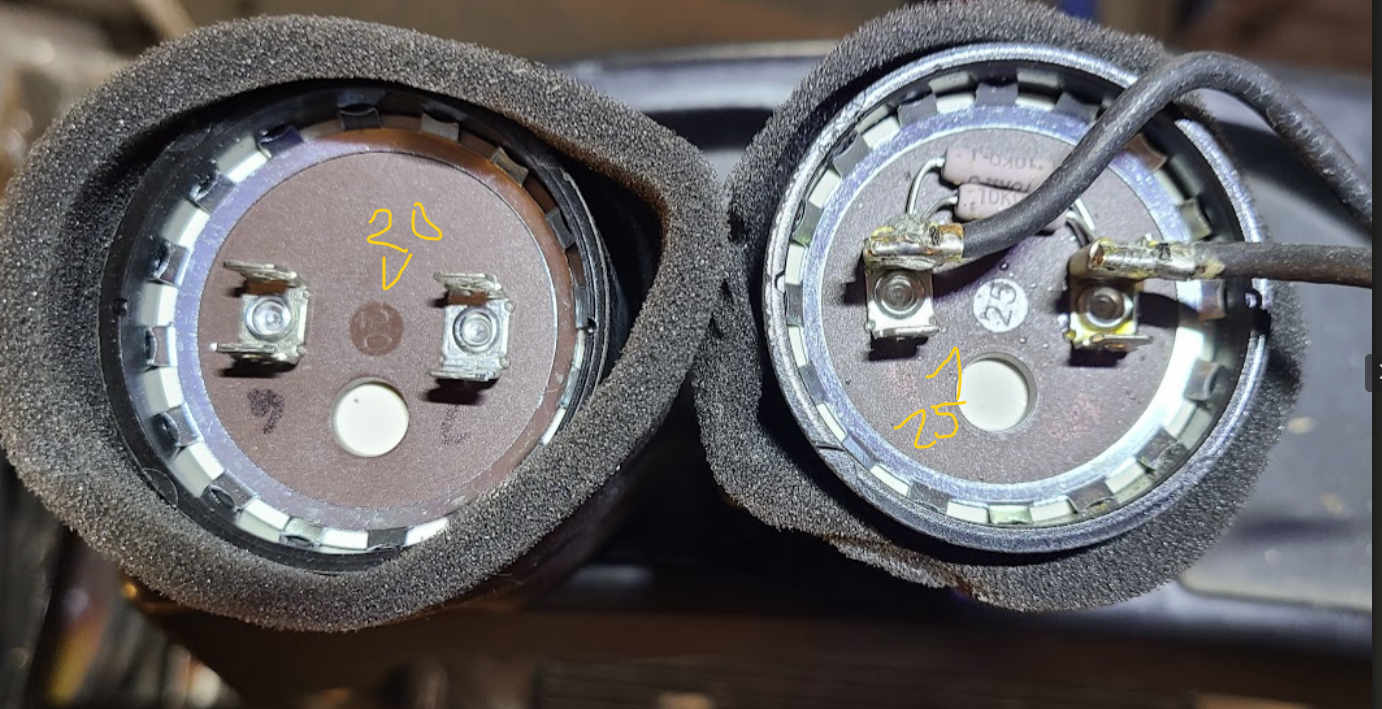

When testing them I took off all the quick connect wires, except for the one with the solder points. But they were disconnected from the other cap.

I tested the one with the resistors and solder like this. No connection to the other one.

The two start caps have the same label only small thing I did notice is that on top one has a 20 and the other a 25, not sure why that is.

When testing them I took off all the quick connect wires, except for the one with the solder points. But they were disconnected from the other cap.

I tested the one with the resistors and solder like this. No connection to the other one.

The two start caps have the same label only small thing I did notice is that on top one has a 20 and the other a 25, not sure why that is.