jward

New Member

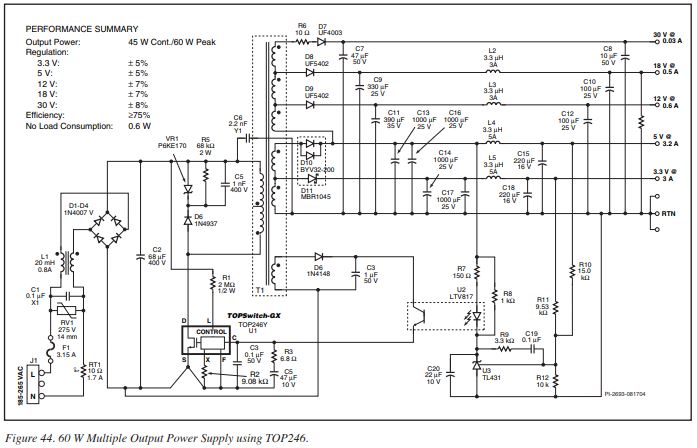

I’m trying to fix a Switching Mode Power Supply for an audio component that is producing only half of the designed output voltage. It has 12V and 5V outputs that are now only 6V and 2.5V. I replaced an obviously bad capacitor on the output of the bridge rectifier and the unit initially worked fine for about a minute until it went off again with the current symptom. It is switched by a Power Integrations TOP245PN (datasheet here). The design of the SMPS is similar to the one in Figure 44 but stripped down to just the 12V/5V outputs with a few component value differences.

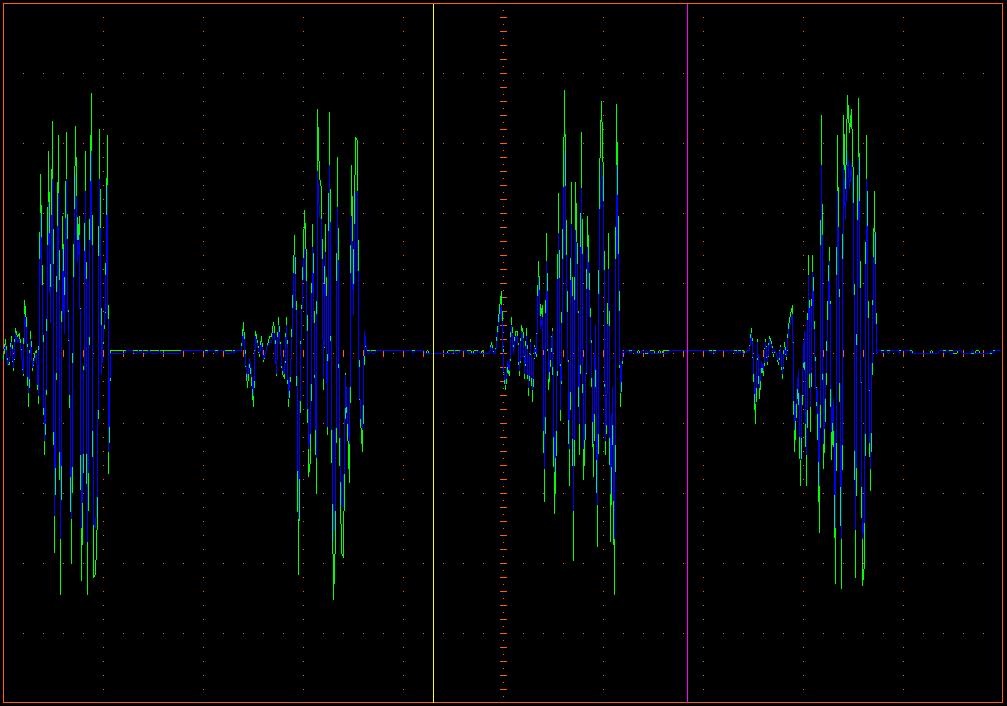

I don’t know what the output of the transformer should normally be but it appears that the duty cycle may only be half of what it should be according to what I’ve seen with an oscope.

The 5V output (blue) is overlaid on the 12V output (green) measured at the transformer secondary. The time between the yellow/magenta markers is ~25ms (40Hz).

Could this apparently half-duty cycle be normal or be the problem?

I don’t know what the output of the transformer should normally be but it appears that the duty cycle may only be half of what it should be according to what I’ve seen with an oscope.

The 5V output (blue) is overlaid on the 12V output (green) measured at the transformer secondary. The time between the yellow/magenta markers is ~25ms (40Hz).

Could this apparently half-duty cycle be normal or be the problem?