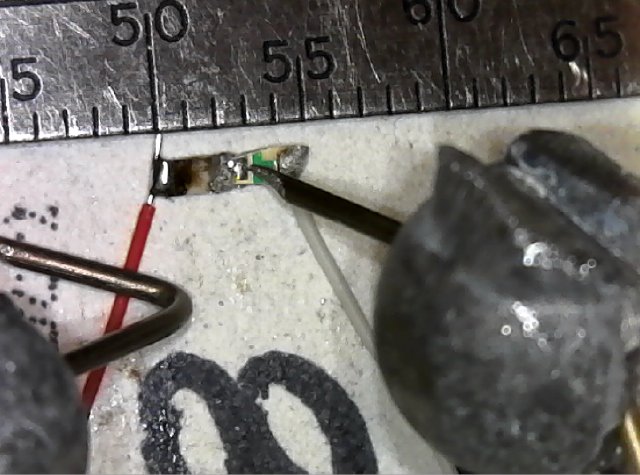

I was having trouble assembling a microscopic SMD resistor, LED and wire wrap wires using dead bug tactics. Then I remembered a third hand tool from welding videos and thought Hmmm.

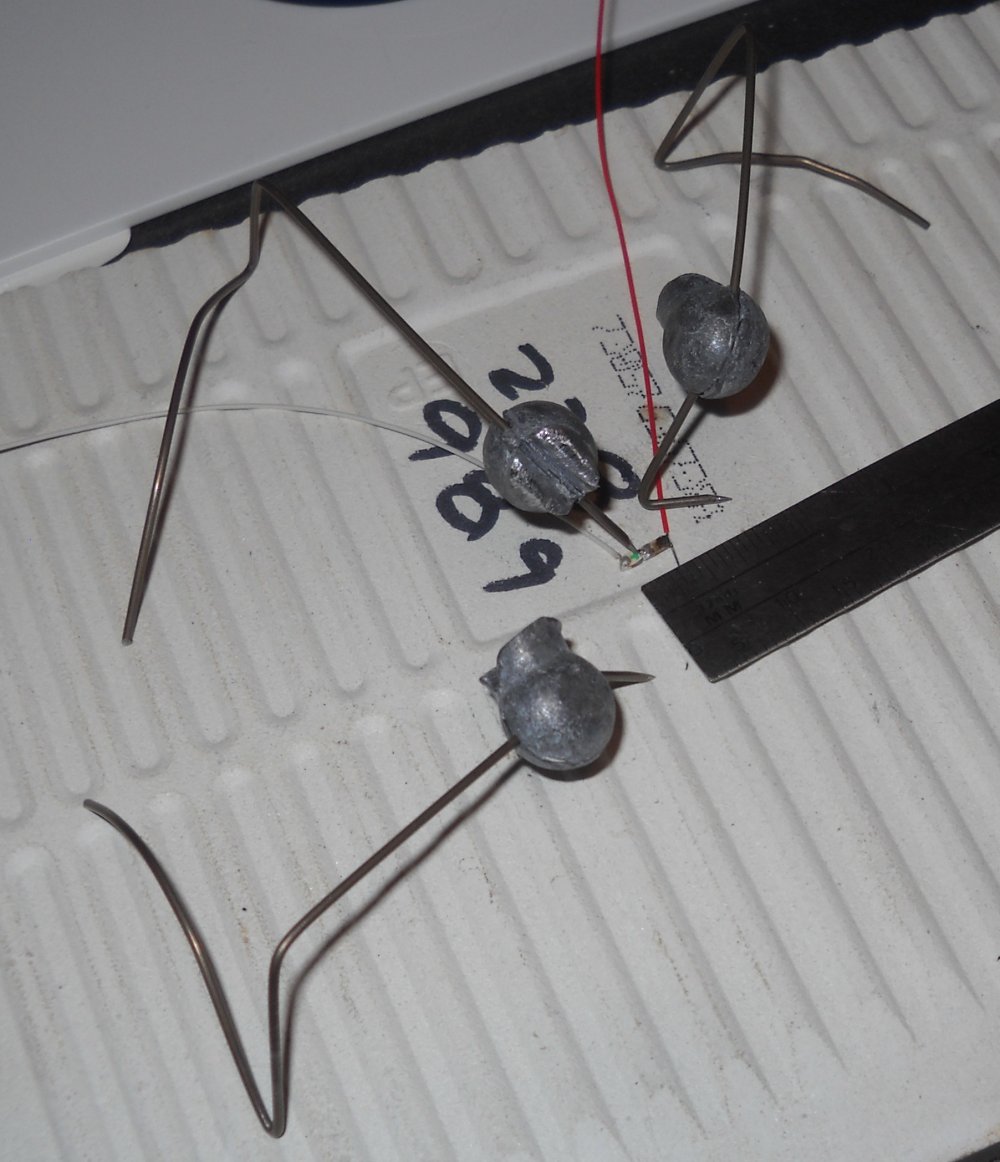

I made these little tripods from really rigid stainless fishing leader (For catching sharks) with the end ground to a point. I used large split shot fishing sinkers to weigh down the business end. There is room for improvement but they worked great for a first time prototype.

I made these little tripods from really rigid stainless fishing leader (For catching sharks) with the end ground to a point. I used large split shot fishing sinkers to weigh down the business end. There is room for improvement but they worked great for a first time prototype.

Last edited: