Hi,

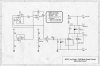

I have a dc motor from a power drill that I am using to drive all thread to move a plexi glass window that slides and hide into the wall up and down.

What I am hoping is I can drive this motor by one momentary switch.

I would like to push the button and it drive the window up out of the wall untill it hits a limit switch which in turn switches the motor into reverse and the next time the button is pressed the motor drives down and stops when it hits the limit switch and the cycle continues up and down.

I will be driving the motor with 12v cd from a computer power supply.

I think the motor might be spinning a little fast when powered straight from the power supply and so I may need some type of speed controller.

Eric

I have a dc motor from a power drill that I am using to drive all thread to move a plexi glass window that slides and hide into the wall up and down.

What I am hoping is I can drive this motor by one momentary switch.

I would like to push the button and it drive the window up out of the wall untill it hits a limit switch which in turn switches the motor into reverse and the next time the button is pressed the motor drives down and stops when it hits the limit switch and the cycle continues up and down.

I will be driving the motor with 12v cd from a computer power supply.

I think the motor might be spinning a little fast when powered straight from the power supply and so I may need some type of speed controller.

Eric