Hey, I am working on a battery charger circuit for SLA small ~1.3Ah 12v. It is part of a greater circuit and will be triggered from a PIC program that checks the voltage of the battery and triggers a charge cycle, breaking it regularly to check on its status.

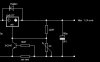

My voltage source is regulated 13.5v and this is the correct voltage I'd like to charge to, however my concern is charge current would need to be limited to ~300mA or something to prevent battery damage, but every circuit idea I find has some fancy regulating charger IC or similar, and I already have a regulated correct voltage. Just trying to find a simple Current restricted Circuit idea that I can trigger using a PIC to switch a FET and charge up the battery?

Thanks in advance!

My voltage source is regulated 13.5v and this is the correct voltage I'd like to charge to, however my concern is charge current would need to be limited to ~300mA or something to prevent battery damage, but every circuit idea I find has some fancy regulating charger IC or similar, and I already have a regulated correct voltage. Just trying to find a simple Current restricted Circuit idea that I can trigger using a PIC to switch a FET and charge up the battery?

Thanks in advance!