PG1995

Active Member

Hi,

Q1:

I was looking for something so that soldering could be avoided. Is silver epoxy a good alternative? I think solder paste still requires soldering.

1: https://www.amazon.com/MG-Chemicals-Silver-Epoxy-Adhesive/dp/B003BDMJSY/

2: https://www.amazon.com/Clean-Temperature-Solder-Paste-Grams/dp/B017RSGPI8/

Q2:

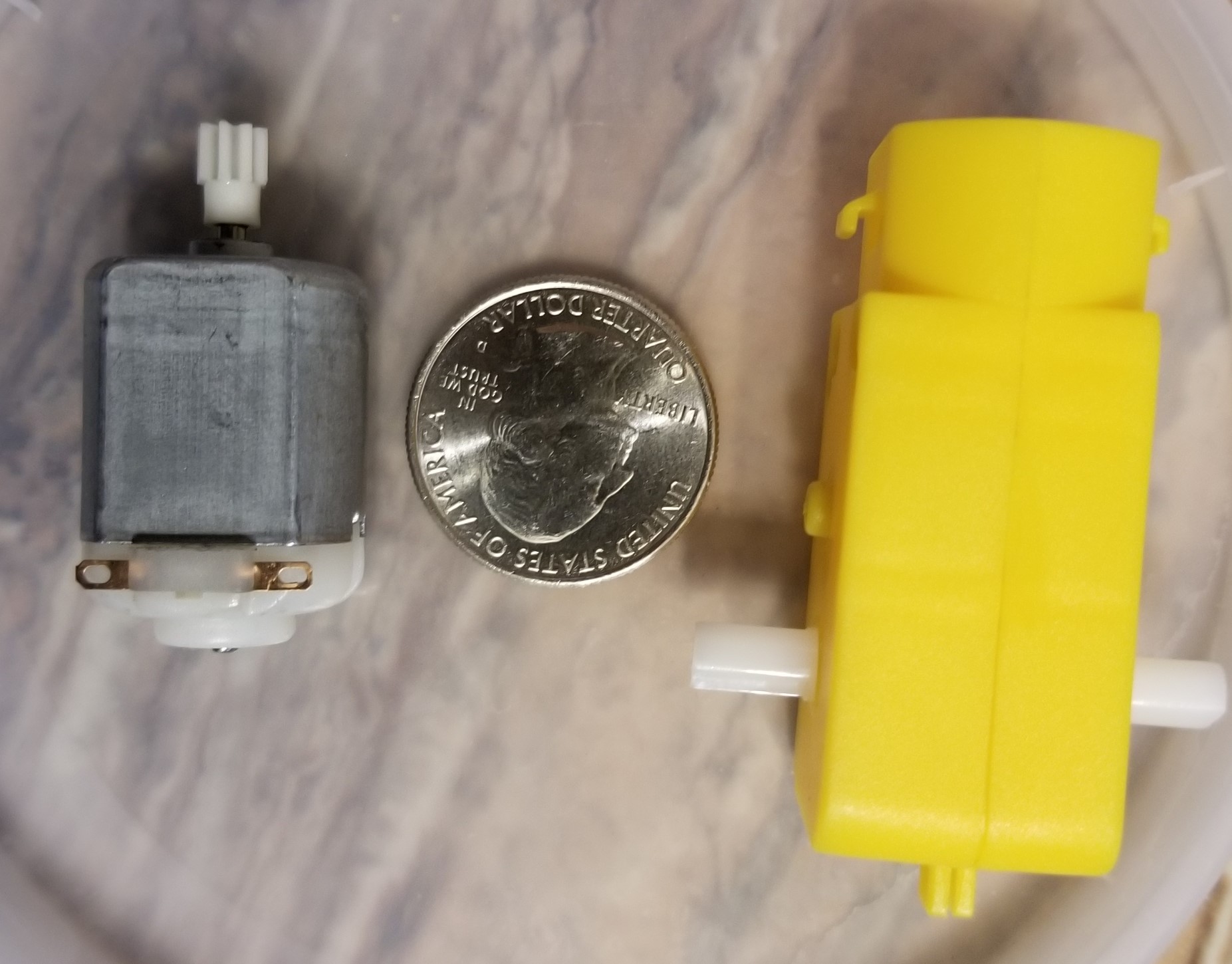

Is there any way to figure out the maximum voltage for the motor shown and maximum possible RPM?I tried to run it at 10 V for 2 minutes, it didn't break. Such motors could be found in robot kits like this one: https://www.amazon.com/Smart-Chassis-Motors-Encoder-Battery/dp/B01LXY7CM3

Thank you for the help!

Q1:

I was looking for something so that soldering could be avoided. Is silver epoxy a good alternative? I think solder paste still requires soldering.

1: https://www.amazon.com/MG-Chemicals-Silver-Epoxy-Adhesive/dp/B003BDMJSY/

2: https://www.amazon.com/Clean-Temperature-Solder-Paste-Grams/dp/B017RSGPI8/

Q2:

Is there any way to figure out the maximum voltage for the motor shown and maximum possible RPM?I tried to run it at 10 V for 2 minutes, it didn't break. Such motors could be found in robot kits like this one: https://www.amazon.com/Smart-Chassis-Motors-Encoder-Battery/dp/B01LXY7CM3

Thank you for the help!