Thanks for your input Chris.

Transformers don't fail very often.

I certainly agree

When they do it's usually because the original design was poor, or the construction was shoddy.

That could easily be correct, in general. In this case I have a feeling it is more a hostile environment that causes the grief ... despite the encapsulation. The ones that fail have mostly been running for some years already ... and only perhaps one out of the 20 - 60 units in a dairy may go faulty.

But to answer your original question, unfortunately no. Or at least I'm not aware of any source of any ready made switch mode transformers for general use.

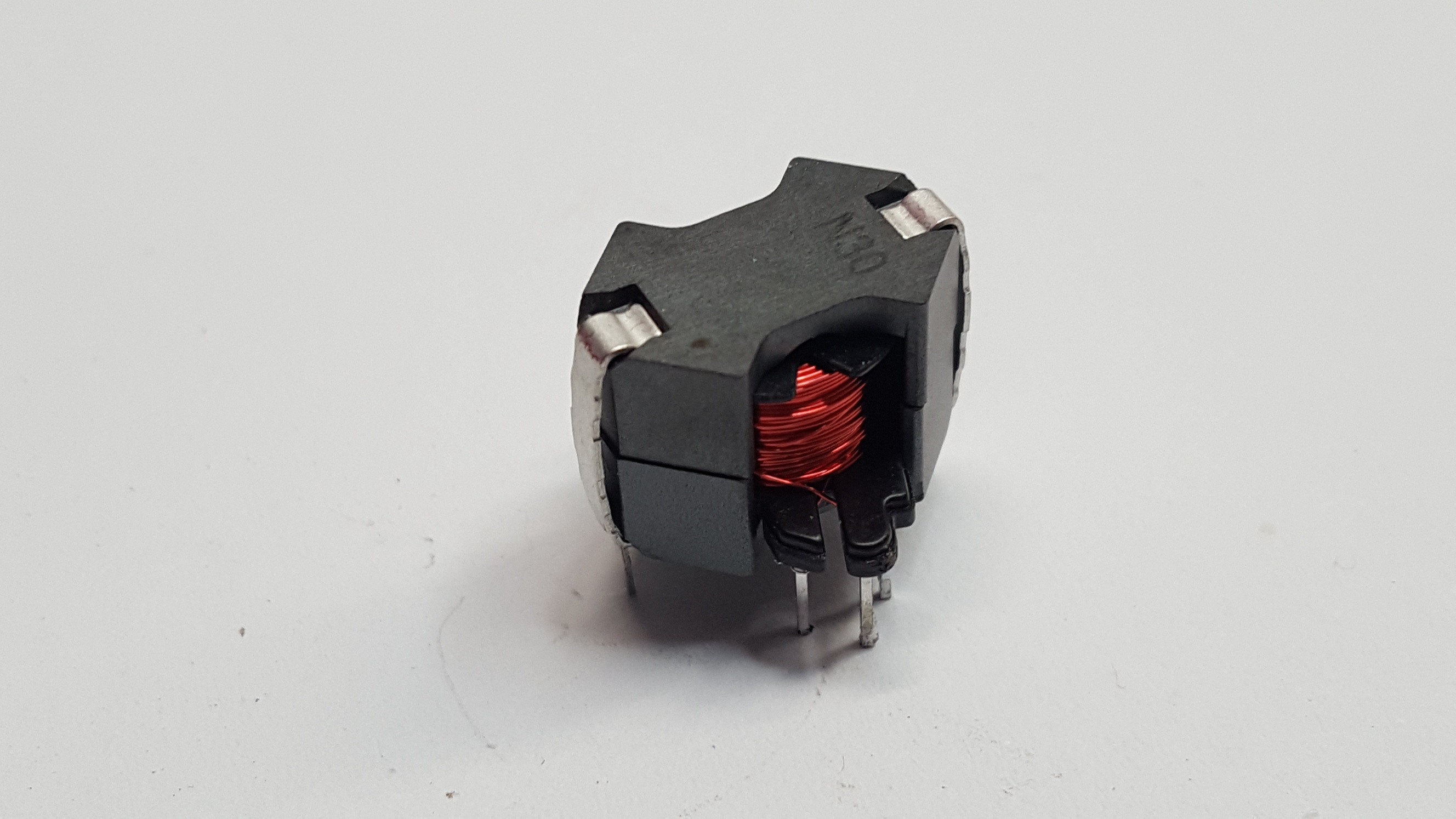

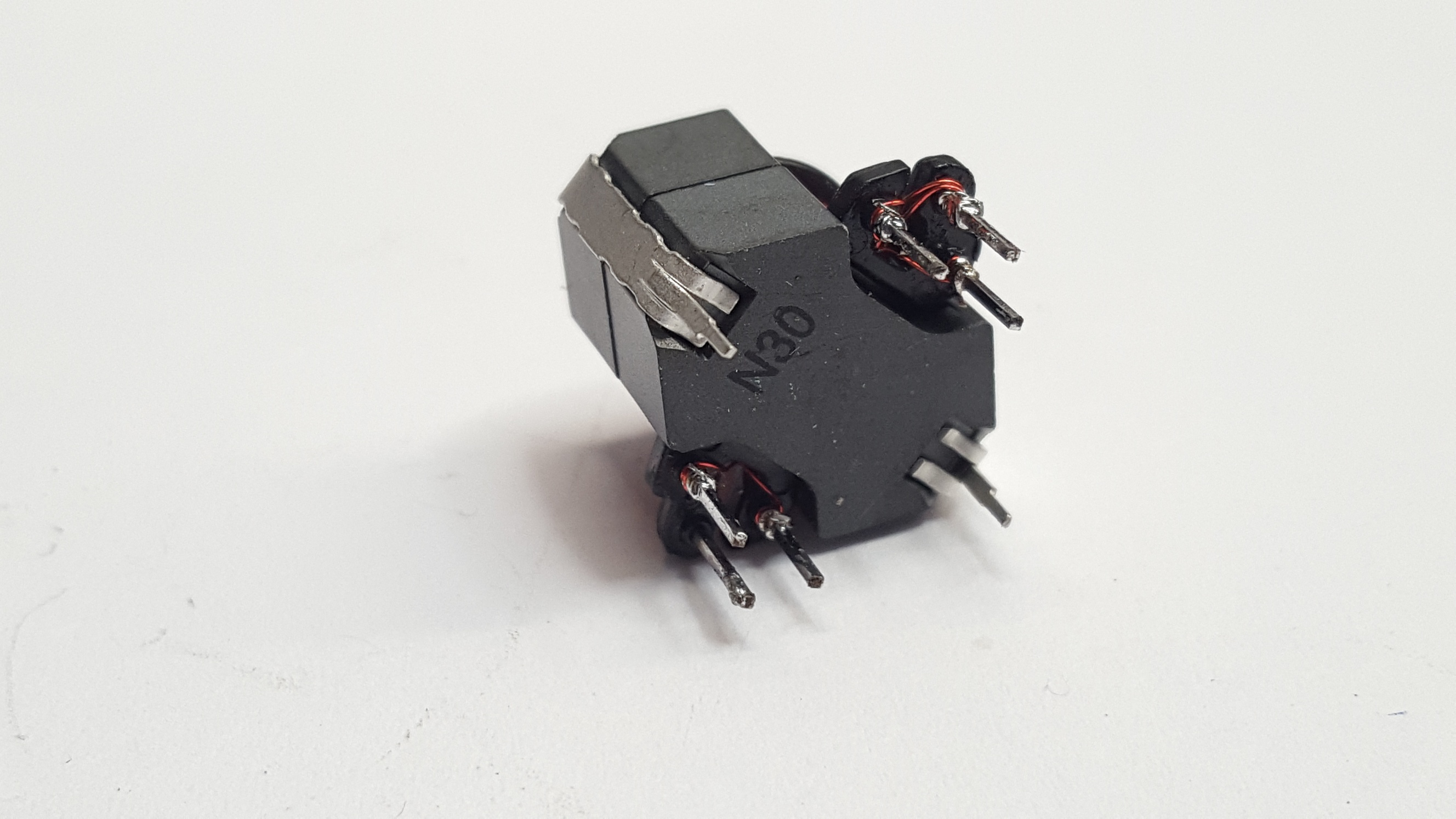

Actually I wasn't really sure how to describe it ... it is not a switch mode tx ... it's more of a signal transformer.

It operates at around 4.7kHz and puts out a signal of around 4 volts unloaded. It has a centre tapped primary and a single secondary winding.

I have looked occasionally over the years for suppliers, but have never found any. Certainly I could get some wound ... but I'd need to buy maybe a thousand ... and I'm only likely to use 20 -30 a year perhaps.

I did recently build a coil winder out of an old battery drill ... with a foot control for speed and reverse ... which helps a lot ... but it's still a pain in the butt.

What are the symptoms of failure, besides the board stops working? Any signs of overheating, etc.?

Does the broken wire look like it was stressed (stretched) that might have caused it to break?

The sensing circuit just stops ... all the rest still works ok.

I've haven't really been able to get one apart without inflicting lots more damage ... so I haven't worked out what goes wrong. It took a number before I could actually tell how it was wound and how many turns etc,

There is one model where the designer used an output socket the same size as the boards 27v power socket ... right alongside each other mind you. No prizes for guessing why some of those die.