A close friend of mine repurposed an old rabbit hutch that he had built into a greenhouse of sorts. I have never actually seen it in person, but I built a simple fan controller with an Arduino UNO, a relay and a DS1820 sensor. LCD and a few buttons and he can set the on:/Off temperatures. It works well and he likes it a lot. It was a fun little project.

We also talked about an actuator to open the ceiling. I have never used an actuator, but it sounds like fun so I got one and have been playing around with it a bit. I know many on here have a lot of experience with such devices and that is why I am writing - with a few specific questions but also to get some sanity check comments.

Here is a pic of the 'hutchouse'.

The ceiling is NOT raised in the pic. The high side of the ceiling can be raised about 8" - that is the task. The hutch stands on legs ~3' high. The body is about 60"" X 30". He said that he thought that the ceiling weighed no more than 25-30 lbs. The blue lines are drawn in to represent additional boards to be added to support the actuator, which would be mounted inside. One bracket on the upright post and the other on the ceiling frame. There is a small amount of floor space which houses the current fan controller mentioned previously and can accomodate the additional PS and circuitry..

I purchased this actuator https://www.ebay.com/itm/6-Stroke-L...e=STRK:MEBIDX:IT&_trksid=p2060353.m2749.l2649

I can't conveniently duplicate the specs in the message but they are listed in the advert.

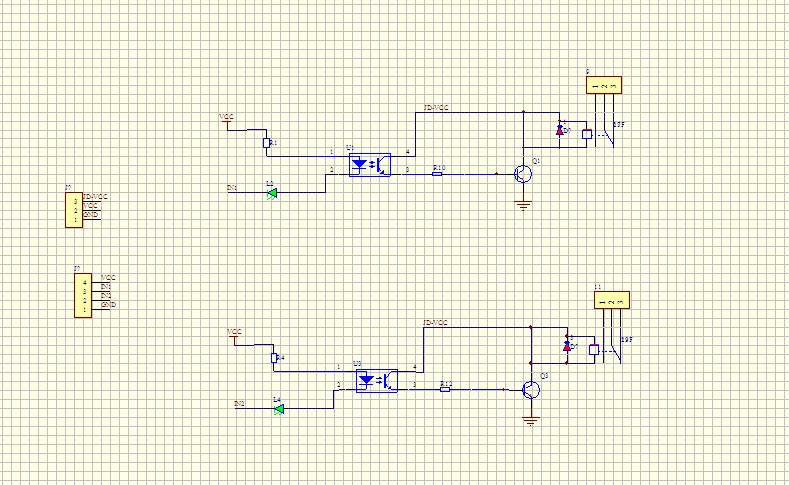

I am using this run-of-the-mill dual relay and an UNO for testing. These are LOW operate and here is the schematic - usual stuff there and I have used these or similar many times. I'm testing using my bench PS.

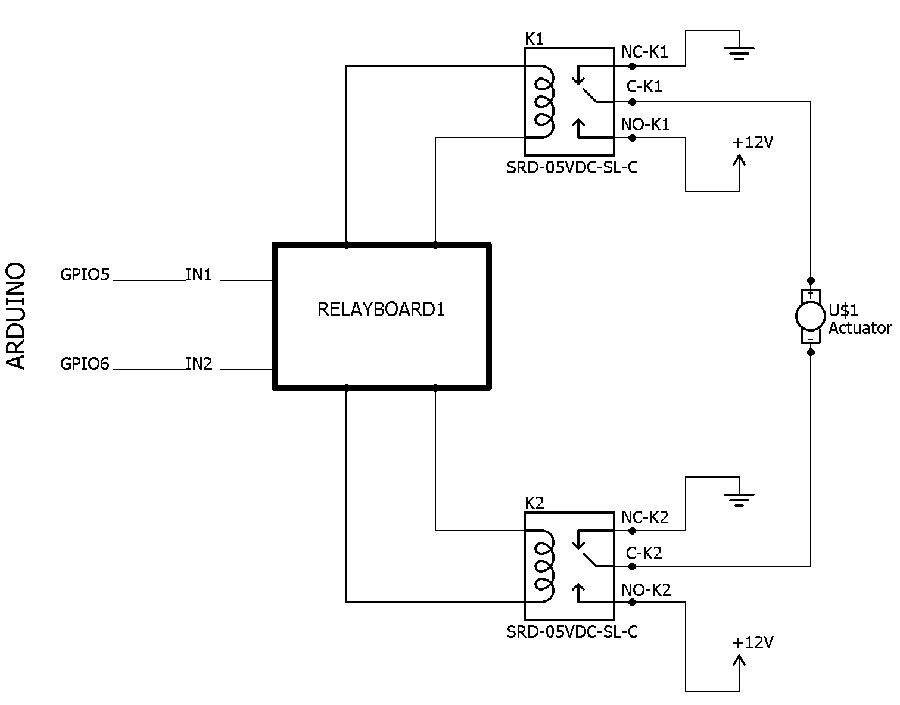

Here is the schematic I am using to control the actuator. I might have come up with this myself but I also might have seen it somewhere, but can't remember. It is pretty simple.

This circuit works fine for testing using simple functions like those below. It will get more complicated.

In my testing, it takes ~14-15 sec for full extension or retraction (basically consistent with the specs). Will that speed change significantly under load? I have it my end to have two or three levels of opening - 2", 4", 6" and to do that by timing, if possible. For the smallest level, I could see a simple read switch and magnet run to an input port to verify it has been raised, but with no position feedback (those cost a whole lot), I don't have any clever ideas (yet) about accomplishing someting like that.

There are limit switches on both ends and the current is cutoff as expected when they are hit. What is the easiest way to verify that or detect a failure. IOW, how can I tap into the 12V line and run it to an input port? Would an opto with resistor work? If yes, where to tap? I am not an EE (if you have not guessed), but I should be able to figure it out...eventually.

The unit claims 900N (225lb) load capacity. That should mange raising one end of a 40lb ceiling - right? Or am I missing something fundamental (again)?

The IP54 rating is far from 'waterproof'. I looked it up and it seemed to be saying it could hold up to a little water spray. Since it would be on the inside, I am hoping that will suffice - I may need to build in a rain detector.

The duty cycle is 25%, so I know that if I operate it for 10 secs, I will not operate it for another 30 sec. That is no big deal programming-wise.

This puzzles me a lot - I see a max current draw of 360-370 mA. The specs say that rated current=3A. I am operating it with no load. Can I expect the draw to jump under load?

All this is a lot of "thinking out loud", but I will appreciate any comments - even laughter.

We also talked about an actuator to open the ceiling. I have never used an actuator, but it sounds like fun so I got one and have been playing around with it a bit. I know many on here have a lot of experience with such devices and that is why I am writing - with a few specific questions but also to get some sanity check comments.

Here is a pic of the 'hutchouse'.

The ceiling is NOT raised in the pic. The high side of the ceiling can be raised about 8" - that is the task. The hutch stands on legs ~3' high. The body is about 60"" X 30". He said that he thought that the ceiling weighed no more than 25-30 lbs. The blue lines are drawn in to represent additional boards to be added to support the actuator, which would be mounted inside. One bracket on the upright post and the other on the ceiling frame. There is a small amount of floor space which houses the current fan controller mentioned previously and can accomodate the additional PS and circuitry..

I purchased this actuator https://www.ebay.com/itm/6-Stroke-L...e=STRK:MEBIDX:IT&_trksid=p2060353.m2749.l2649

I can't conveniently duplicate the specs in the message but they are listed in the advert.

I am using this run-of-the-mill dual relay and an UNO for testing. These are LOW operate and here is the schematic - usual stuff there and I have used these or similar many times. I'm testing using my bench PS.

Here is the schematic I am using to control the actuator. I might have come up with this myself but I also might have seen it somewhere, but can't remember. It is pretty simple.

This circuit works fine for testing using simple functions like those below. It will get more complicated.

C-like:

void RelayOff(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, HIGH);

}

void RelayExtend(){

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

}

void RelayContract(){

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

}In my testing, it takes ~14-15 sec for full extension or retraction (basically consistent with the specs). Will that speed change significantly under load? I have it my end to have two or three levels of opening - 2", 4", 6" and to do that by timing, if possible. For the smallest level, I could see a simple read switch and magnet run to an input port to verify it has been raised, but with no position feedback (those cost a whole lot), I don't have any clever ideas (yet) about accomplishing someting like that.

There are limit switches on both ends and the current is cutoff as expected when they are hit. What is the easiest way to verify that or detect a failure. IOW, how can I tap into the 12V line and run it to an input port? Would an opto with resistor work? If yes, where to tap? I am not an EE (if you have not guessed), but I should be able to figure it out...eventually.

The unit claims 900N (225lb) load capacity. That should mange raising one end of a 40lb ceiling - right? Or am I missing something fundamental (again)?

The IP54 rating is far from 'waterproof'. I looked it up and it seemed to be saying it could hold up to a little water spray. Since it would be on the inside, I am hoping that will suffice - I may need to build in a rain detector.

The duty cycle is 25%, so I know that if I operate it for 10 secs, I will not operate it for another 30 sec. That is no big deal programming-wise.

This puzzles me a lot - I see a max current draw of 360-370 mA. The specs say that rated current=3A. I am operating it with no load. Can I expect the draw to jump under load?

All this is a lot of "thinking out loud", but I will appreciate any comments - even laughter.