As Nigel says, a 32 bit controller will not in itself improve the printer function in any way.

The actual processing requirements for 3D printing are minimal.

eg. A CNC machine tool controller we designed in the early 1980s that ran on a 4MHz CPU worked to orders of magnitude higher precision and speed than a current 3D printer needs. It's internal precision was better than a tenth of a micron.

More CPU power may be needed for such as a built-in graphics touchscreen and other gimmicks which are really better off in a separate device - the printers job is to print!

Your priorities should be:

Compatibility with whatever physical requirement the printer mechanics - eg. linear slides, delta mechanics or whatever, and the total number of motor drivers needed and supported - if you may want to go to such as colour-blending extruders you need lots of motor outputs, that not many boards have!

Then, the controller out of those that has the best firmware and software support. Some types have rather buggy or closed firmware while others are really excellent.

Repetier, Marlin and Reprap are all reputedly good.

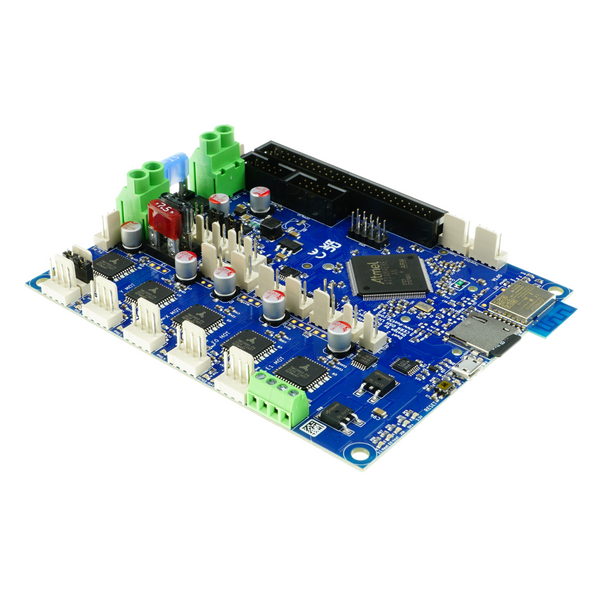

Of the 32 but setups available, the Duet 2 looks to be one of the best options. That supports Reprap firmware, and many motor drivers.

In stock, ready to ship. Internal antenna has been discontinued in favor of external antenna. Documentation can be found here. Features: Duet 2 Wifi features include a dedicated wifi module, higher stepper and heater current ratings, and more accurate temperature control. More features below...

www.filastruder.com

Also the Smoothieboard, but only five motor drivers.

**broken link removed**

This not a 32 bit one, but with lots of outputs and interconnectivity, plus multi-firmware compatibility:

Get the best deals on Other Consumer Electronics when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

www.ebay.com