My home has hot-water heating (aka hydronic) with only one furnace. Domestic hot water is heated with that furnace as well and uses a separate heat exchanger loop. Excluding an outside wood burner that can be used as an alternative heat source, there are 6 zones in the house: domestic hot water, basement, garage, upstairs, downstairs, and an additional space. The furnace is propane fired and is rated at 105,000 BTU/h (approximately 31 kW or 12 hp). House is reasonably energy efficient as it was built in 1993. There is no need for the furnace to run continuously; moreover, frequent cycling of the furnace wastes propane.

Domestic hot water (DHW) has priority over house zones. The house zones are all wired in parallel (OR'd). If only one zone calls for heat, the furnace turns on. It is the latter fact that can lead to frequent cycling of the furnace. Original thermostats were Honeywell 87A's and had mercury switches, and by carefully setting them differently, I could reduce cycling a little. Some have gotten a bit funky and unreliable. Of course, direct replacements are no longer available. Honeywell's digital replacements do not allow adjustment of the spread (i.e., hysteresis between call for heat and satisfied). They do have an adjustment for number of cycles per hour. The values vary from 1 to 9 (i.e., 1,3,5,9). I am not 100% certain what the number represents. It appears from blogs that the duty cycle is set at 50% and that, for example, a value of "3" means the furnace is on for 10 minutes, then off for at least 10 minutes, until the demand for heat is justified. It is not clear whether the furnace will stay on for more than 10 minutes to satisfy the demand for heat. However, if the demand is met before the 10 minutes elapses, the furnace will turn off. (I am currently testing one I installed yesterday.) The alternative is a thermostat that has an adjustable spread. I have tentatively decided on using a Honeywell version, modelRTH6350D.

Here is the wiring for the house zones:

When the "End Switch" is closed, the furnace comes on. Since there is no interconnection between the thermostats, it is possible that one will cycle until satisfied, then another and so forth, which will lead to frequent cycling of the furnace regardless of the cycles/hour setting for each thermostat.

QUESTION:

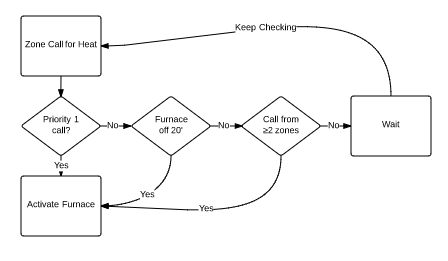

The purpose of this post is to get opinions on prioritization schema for the in living space . I am considering inserting an MCU between the household zone end switches and the furnace relay that will prevent rapid cycling by sequential calls for heat from each zone. Here is a tentative scheme:

Any comments or suggestions?

John

Domestic hot water (DHW) has priority over house zones. The house zones are all wired in parallel (OR'd). If only one zone calls for heat, the furnace turns on. It is the latter fact that can lead to frequent cycling of the furnace. Original thermostats were Honeywell 87A's and had mercury switches, and by carefully setting them differently, I could reduce cycling a little. Some have gotten a bit funky and unreliable. Of course, direct replacements are no longer available. Honeywell's digital replacements do not allow adjustment of the spread (i.e., hysteresis between call for heat and satisfied). They do have an adjustment for number of cycles per hour. The values vary from 1 to 9 (i.e., 1,3,5,9). I am not 100% certain what the number represents. It appears from blogs that the duty cycle is set at 50% and that, for example, a value of "3" means the furnace is on for 10 minutes, then off for at least 10 minutes, until the demand for heat is justified. It is not clear whether the furnace will stay on for more than 10 minutes to satisfy the demand for heat. However, if the demand is met before the 10 minutes elapses, the furnace will turn off. (I am currently testing one I installed yesterday.) The alternative is a thermostat that has an adjustable spread. I have tentatively decided on using a Honeywell version, modelRTH6350D.

Here is the wiring for the house zones:

When the "End Switch" is closed, the furnace comes on. Since there is no interconnection between the thermostats, it is possible that one will cycle until satisfied, then another and so forth, which will lead to frequent cycling of the furnace regardless of the cycles/hour setting for each thermostat.

QUESTION:

The purpose of this post is to get opinions on prioritization schema for the in living space . I am considering inserting an MCU between the household zone end switches and the furnace relay that will prevent rapid cycling by sequential calls for heat from each zone. Here is a tentative scheme:

Any comments or suggestions?

John