Huttojb1

Member

Hey all

Need help with a PWM signal.

I have a PWM signal which when read on a DMM I see a RMS of 14v, 10v, 8v, 6v, 4v and 2v depending on input selection.

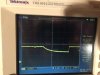

Unfortunately I am unable to measure the signal through my PICCO scope as it's not quick enough.

I'm looking to change the signal to a DC voltage dependant of the input selection. So I'm looking to have a voltage between 0v and 5v to read into my ADC. So I'll probable use a potential divider to drop the voltage by a third and looking at a low pass filter / RC Filter to smooth the PWM to a DC voltage and the DC voltage to vary in relation to the Duty cycle.

Problem is, I do not know the frequency of the PWM, I have asked to borrow my friends scope but is there anything I can do to achieve this without knowing the frequency

Jason.

Need help with a PWM signal.

I have a PWM signal which when read on a DMM I see a RMS of 14v, 10v, 8v, 6v, 4v and 2v depending on input selection.

Unfortunately I am unable to measure the signal through my PICCO scope as it's not quick enough.

I'm looking to change the signal to a DC voltage dependant of the input selection. So I'm looking to have a voltage between 0v and 5v to read into my ADC. So I'll probable use a potential divider to drop the voltage by a third and looking at a low pass filter / RC Filter to smooth the PWM to a DC voltage and the DC voltage to vary in relation to the Duty cycle.

Problem is, I do not know the frequency of the PWM, I have asked to borrow my friends scope but is there anything I can do to achieve this without knowing the frequency

Jason.