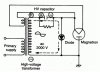

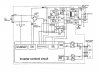

the circuit you uploaded is from a microwave oven that uses a flyback converter operating at a higher frequency than the AC power. you have to realize that the power transformer in the first schematic is for 50Hz, the second one somewhere around 5-10kHz. if you try driving the first one at 10hz, you will lose most of your energy as heat in the transformer which is designed for 50Hz operation. the reactance of the primary winding will be much lower, but the wire resistance will stay the same, this also means that the reactance will no longer have the same phase difference from the wire resistance, and you will overheat the primary. i'm beginning to get the picture this project isn't about cooking, or the 10 second duty cycle window wouldn't be an issue. i'm guessing you want to make either a radar (it's going to take a lot more than simple modifications to make that work) or something a bit more hazardous???

like i said earlier, magnetrons are not linear. they act like a regular diode below a certain voltage when the threshold voltage is reached, electrons are no longer traveling directly to the plate. the magnetic field curves their path, and they begin spiralling towards the plate. at a certain critical voltage the electrons are just grazing across the surface of the plate, and this sets up oscillation in the resonant cavities in the plate, which is the source of the microwave RF. above this critical voltage, the electrons never get near the plate, and the oscillation stops. now there's no tube current, no microwaves being produced, this is the cutoff voltage of the magnetron. the active portion of the curve where microwaves are being generated is actually a negative resistance region. if you pulse width modulate the power going into the transformer, the voltage on the secondary side will average out, and you may end up with the tube in diode mode, the tube in active mode (a very narrow region) or in cutoff mode. you want to avoid diode mode, because the cathode will likely overheat and burn out, and you want to avoid cutoff mode, because the voltage across an open circuit tube will likely find somewhere to arc over. within the active portion of the curve, there is really very little variation in power output, except for the nonlinear edges between diode mode and active mode, and between cutoff mode and active mode. the active mode is so narrowly defined that fine grained control of output power is not really possible. if you want a source of microwaves that can be easily controlled, it's better to use a reflex klystron, or a Gunn diode. when i was in high school i found a box of some really weird looking parts in the electronics shop. the teacher said i could take them home, as they were just taking up space. when i got the box home i got a better chance to see what was there. there were a bunch of reflex klystrons similar to this one

https://www.bmisurplus.com/products/46200-etheric-beam-locator-varian-va-220b-klystron-tube . there were two demo units that had an amplitude modulated klystron in one side, and a waveguide with crystal detector on the other side, and with horn antennas mounted on the boxes, you could talk full duplex on them, but their range was limited to about 10 feet.