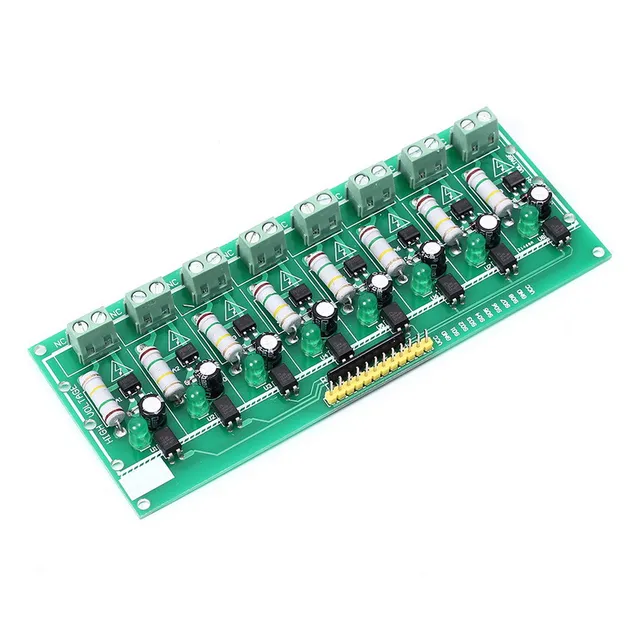

Hello. I am using this kind of AC sensing or digital input to a Raspberry Pi Board PC. There are 8 AC signals that suddenly drop in different order and times, and I try to determine the order and milliseconds between channels drops.

My problem is that my results change with different AC optocoupler boards from same manufacturer. I need at least 1ms precision and I see differences up to 50ms between boards. For example:

Channels Falling Order

BOARD A : CH1, +2ms CH2, +15ms CH3, +2ms CH4, .... (Repetitive beween tests)

BOARD B: CH2, +20ms CH3, +5ms CH4, +25ms CH1 .... (Repetitive between tests, CH1 is delayed 50 ms in Board B)

little differences in capacitors or something?

Does anybody know what kind of precision or error one can expect for AC drops with this kind of circuits? Do I need to calibrate my C program for earch board? is there any alternative?

**broken link removed**

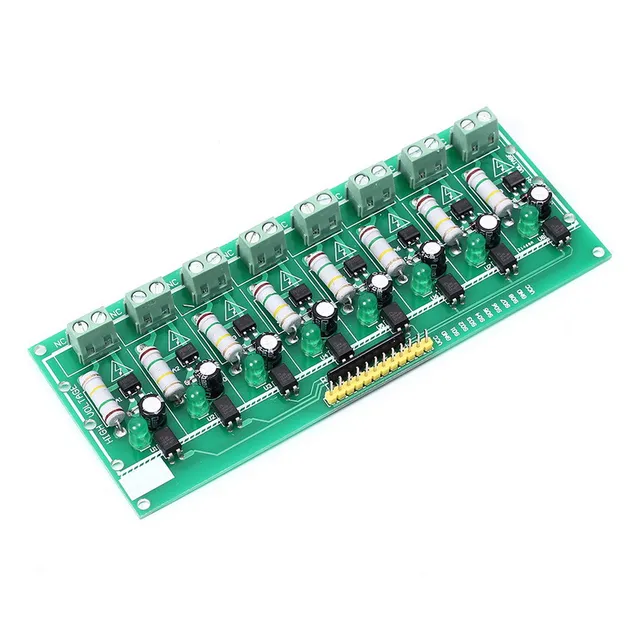

My problem is that my results change with different AC optocoupler boards from same manufacturer. I need at least 1ms precision and I see differences up to 50ms between boards. For example:

Channels Falling Order

BOARD A : CH1, +2ms CH2, +15ms CH3, +2ms CH4, .... (Repetitive beween tests)

BOARD B: CH2, +20ms CH3, +5ms CH4, +25ms CH1 .... (Repetitive between tests, CH1 is delayed 50 ms in Board B)

little differences in capacitors or something?

Does anybody know what kind of precision or error one can expect for AC drops with this kind of circuits? Do I need to calibrate my C program for earch board? is there any alternative?

**broken link removed**