AtomSoft

Well-Known Member

Before I go and hot glue some Pogo pins tonight.

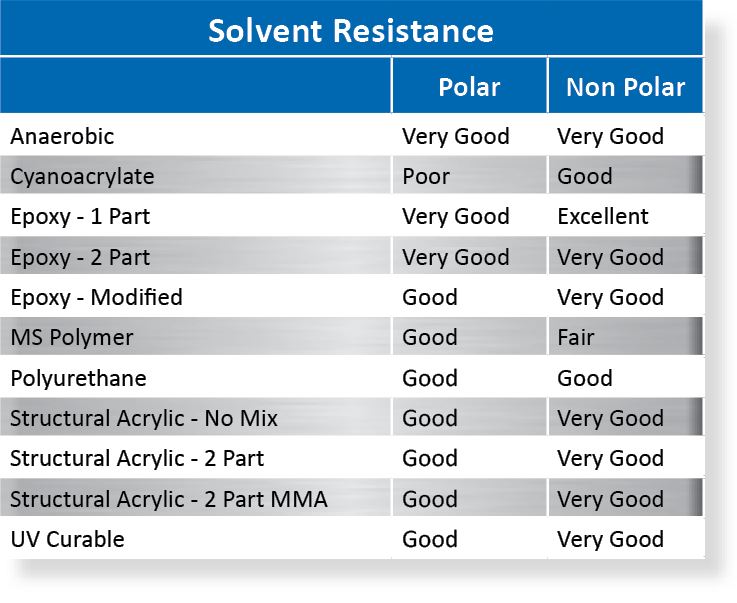

Does anyone know of a good or better way to secure Pogo pins to some acrylic? Would crazy glue work? Or standard acrylic type glue?

Pogo looks good so I assume it is gold or copper.. so a metal to acrylic? I can clean Pogo with alcohol and use gloves to make sure it stays clean. Now what's the best glue to use?

Does anyone know of a good or better way to secure Pogo pins to some acrylic? Would crazy glue work? Or standard acrylic type glue?

Pogo looks good so I assume it is gold or copper.. so a metal to acrylic? I can clean Pogo with alcohol and use gloves to make sure it stays clean. Now what's the best glue to use?