Yea about that. I 've worked on enough machines to know the what and why of the troubleshooting process and thus that's why I asked you for specific voltage readings relating to the power flow through the machine early in the thread to which you did not provide.

Without that information all I could do is speculate and I am not a speculating person when it comes to repairing things I understand very well but do not have direct access or properly requested data for so all you got from me was 'garbage in gets garbage out' based responses as in, you provide nothing I can use I provide nothing you can use which is where the "which is it?" response came from being from the technical troubleshooting standpoint there will be no striking arc discharge at the torch head between it and the work if the ignition circuit is not working yet you obviously had it it so I too it that it was working.

However had you mentioned that your machine used a spark gap based ignition systems (which you did not) I would have advised you to clean it and adjust it to see if it changed the ignition striking arc appearance which could have lead to you getting your machine going at that point.

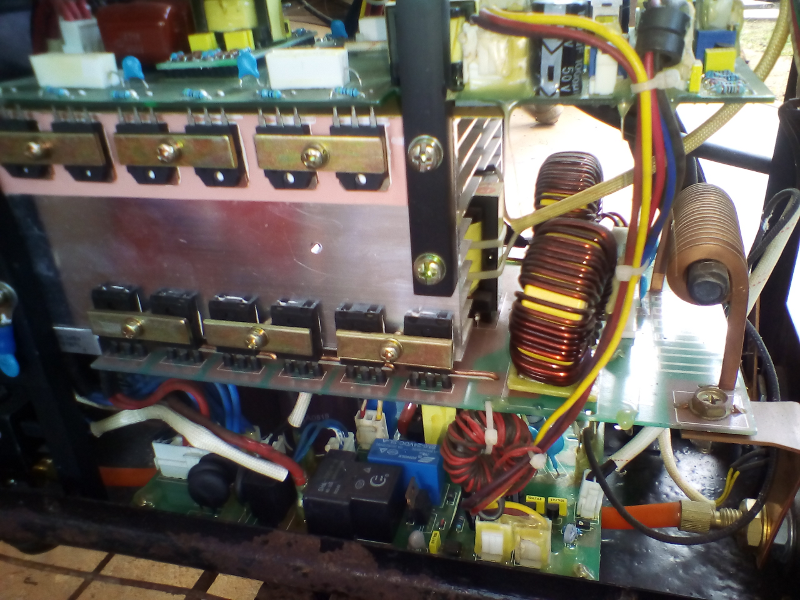

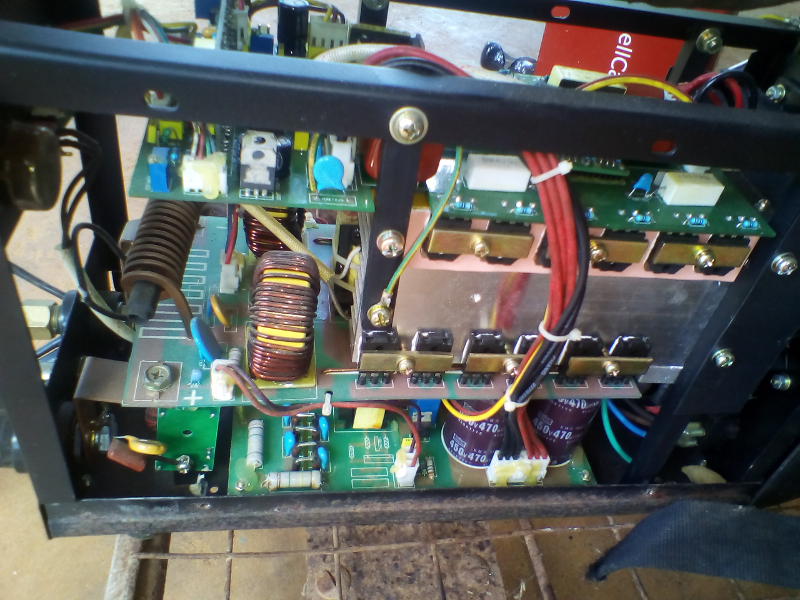

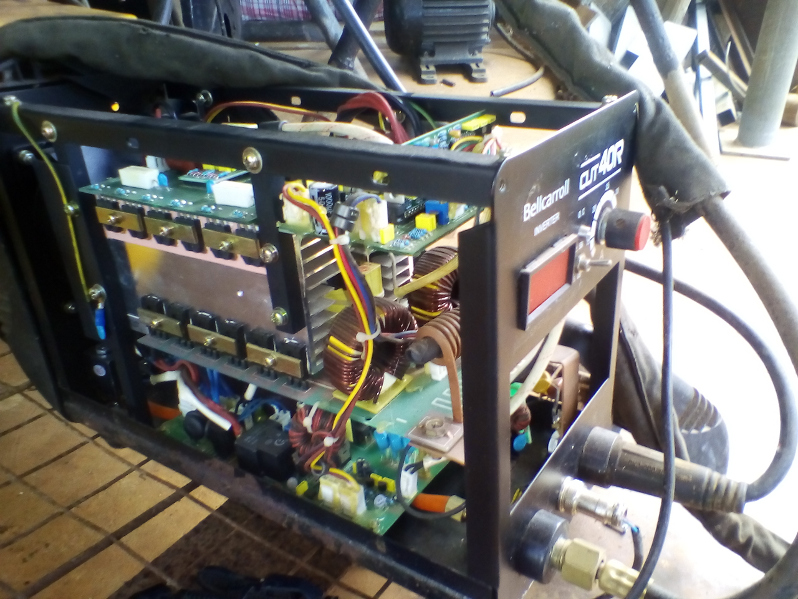

The pictures were done well but lacked any degree of purposeful clarity to the exact build design of your machine. I could not find anything in them that clearly showed it to use a spark gap based ignition system and you also never once mentioned it until the end when you got lucky and figured it out yourself.

Simply put, I asked you for specific information which relate to what is for me standard troubleshooting flow chart practices to which you did not provide so I put very little effort into trying to solve your problem. In my troubleshooting practices those who can not follow instructions and provide me with the information I need do not get to go to the next step in finding a solution to their problem.

As far as my attitude goes, well, if you dealt with as many people as I have who just like you can't follow instructions, give little needed information and then get all self righteous when they do stumble on to the solution to their problem ( and you most certainly did all of those) by more luck than anything, heck yea, you will start to realize where my attitude is coming from as well.

BTW, if you ever come back here with another question about your machine or anything else I will put this thread and its outcome into consideration over helping you even if I know what the solution to you problem is right from the first post. You might get a solution in my first response or you may spend days/weeks working through the problem based on others speculations ultimately to end up with no answers that work while I sit back and consider how things ended in this thread.