Mikebits

Well-Known Member

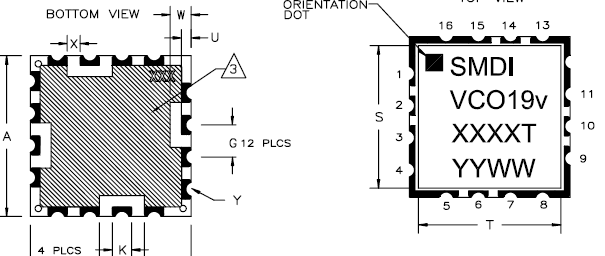

Greetings ETO land. I have a need to build some PCB's (RF Filters), that can be soldered onto another PCB as though it were a component. Much like the VCO part pictured below. So my question is, how does one go about laying out a board like this? What I mean is, I imagine I make the circuit board with the footprint like below, but somehow, there needs to be some breakoff point thus creating little pcb components. So has anyone done something like this and can you provide a little write up how I should proceed. I should mention that the part, has copper going along the side like a plated through hole cut in half, thats the tricky part to me.

Thanks

Thanks