zachtheterrible

Active Member

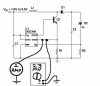

Yup, you heard right, I want to use the zxsc400 instead of the zxsc100. The main reason is that the current output only drops by .01amps when the battery goes from 3.3V to 1.8V! Can't say that for the zxsc100.

The other reason is that the component count is smaller and I was able to get all SMT parts for this circuit.

I'm having one problem with it though. It is the current sense resistor, R1, which is a 17milliohm resistor. This is what the datsheet says:

I did exactly what it said and measured at the current sense pin. Problem is, I got 23mV, which means that my track resistance is too high.

I'm just wondering if I'm doing everything right? I have everything connected exactly as in the diagram. Ground is a piece wire sticking out from my board.

Also, how do I improve the conductivity? I have a layer of solder over the entire part of the circuit that is conducting the 1 amp.

The other reason is that the component count is smaller and I was able to get all SMT parts for this circuit.

I'm having one problem with it though. It is the current sense resistor, R1, which is a 17milliohm resistor. This is what the datsheet says:

R1 is small and it is strongly advised to take track resistance into account. A proven method is to source a 1A current from the sense pin to the ground pin and check for 16-17mV. This resistor can be made from a 15 milliohm resistor with the track resistance contributing the difference.

I did exactly what it said and measured at the current sense pin. Problem is, I got 23mV, which means that my track resistance is too high.

I'm just wondering if I'm doing everything right? I have everything connected exactly as in the diagram. Ground is a piece wire sticking out from my board.

Also, how do I improve the conductivity? I have a layer of solder over the entire part of the circuit that is conducting the 1 amp.