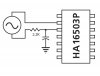

I'm modifying an old super 8 movie camera to have it's timing controlled by interfacing it with a microcontroller (ATmega168). I pulled the old motor out to figure out how it was originally wired. I've attached a couple of pictures of the motor. It's a dc motor powered by the red and black wires, the yellow wire is a ground to the case and the two blue wires come from a little alternator that piggybacks on the back end of the shaft and generates a frequency proportional to the shaft speed. I included a diagram of the way the alternator was wired to a chip on the control board. It was a Hitachi chip (HA16503P) but since it was made in the early 80's I can't find a data sheet on the web for it so I'm not sure what it is. I'm wondering if anyone has any thoughts on this. What I'm trying to do is convert the ac signal to a series of pulses that I can feed into the µcontroller. When the motor is running with no load at 9 volts the alternator outputs about 9.7 volts ac.

Thanks for any help.

Thanks for any help.

Attachments

Last edited: