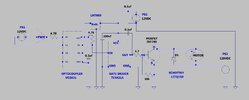

#1... "The 5V supply should go directly to pin 8 of the VO2631; the 4K7 should be between VCC and V1 pins".

OK, so 5vdc- no resistor to VCC on the opto. Didn't know how much power it could take, is why I did it. The gate driver wouldn't even work with the resistor. And 4.7K across A1 and VCC on the opto. Correct?

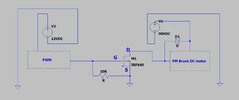

#2 .. "And, you have the MOSFET across the motor so it shorts the 120V supply, rather than in series with the motor!"

Yea, I see where I got that wrong. It was 1:45am and I put that in at the last min. Haven't even tried to hook that up yet. Thanks, I fix it!

#3 .. "Otherwise: You need either a logic-level MOSFET or use a 12V supply for the gate drive circuit (plus a small 5V reg, 7805, to drop that to 5V for the opto)". OK so instead of a 5v PS use a 12vdc and a LM7805 reg. (I got em) to power the opto, but 12v supply for the TC4421A. Is that correct ?

#4 .. "You also need a low value series resistor between the 4421 outputs and MOSFET gate, to limit the peak current. 4.7 Ohms may be suitable"

OK, From the "out" on the TC4421A to the mosfet gate a 4.7 ohm res. or a 4.7K ?

#5 .. "I'd suggest adding some reservoir and decoupling caps to the power (across VCC & GND) for the opto and gate driver ICs, eg. 0.1uF ceramics on each plus eg. 100uF against the gate driver"

OK, 0.1uF ceramics on the P.S. outputs. Got that. Where does the 100uf go ? I have seen a cap between G and S along with the res. and also seen a cap across G and D on the fet. What is correct ? Also I have seen big diodes on some schematics with higher voltages/current. Is this something I should look at ?

I will correct my drawing and repost it. Thanks !