Hi everyone,

Firstly I've been looking for a forum like this one for a long time, its great to see a popular electronics forum with people helping eachother.

Ok, now to my project.

I am trying to build a timer for mains appliances i.e. stereo's, tvs etc. that on the outside is a very simple box that you plug into the wall, then turn a dial to the length of time before it cuts the power to whatever device you have plugged in to 'this' device.

I've found a couple of kits on an american site that do this job, but 1 they are from America which complicates postage etc. plus 2 I'd prefer to make it from scratch. But so you can get a better idea of my projects here are the 2 kits.

**broken link removed**

**broken link removed**

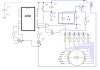

Now, I've sketched out some quick ideas of how it may work, but please be warned I am a complete amatuer And my schematics may be completely wrong.

And my schematics may be completely wrong.

I was hoping some of you guys and girls could help me out in any way you can? i.e. tell me where my design is wrong, suggest how I could achieve this with a completely different circuit etc.

Here are a couple of the thoughts I've had so far. (where the +9v comes in will be after a transformer)

**broken link removed****broken link removed**

I highly appreciate any help you can give me with this

Splash :delta:

Firstly I've been looking for a forum like this one for a long time, its great to see a popular electronics forum with people helping eachother.

Ok, now to my project.

I am trying to build a timer for mains appliances i.e. stereo's, tvs etc. that on the outside is a very simple box that you plug into the wall, then turn a dial to the length of time before it cuts the power to whatever device you have plugged in to 'this' device.

I've found a couple of kits on an american site that do this job, but 1 they are from America which complicates postage etc. plus 2 I'd prefer to make it from scratch. But so you can get a better idea of my projects here are the 2 kits.

**broken link removed**

**broken link removed**

Now, I've sketched out some quick ideas of how it may work, but please be warned I am a complete amatuer

I was hoping some of you guys and girls could help me out in any way you can? i.e. tell me where my design is wrong, suggest how I could achieve this with a completely different circuit etc.

Here are a couple of the thoughts I've had so far. (where the +9v comes in will be after a transformer)

**broken link removed****broken link removed**

I highly appreciate any help you can give me with this

Splash :delta: