Hello,

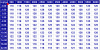

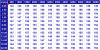

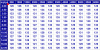

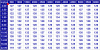

I have a Landi Renzo LPG system on my car, and using Landi Renzo Omegas software. After a bad work of a technician the consumption increased a lot and became laggy and jerky. I auto-calibrated it with the software, but I don't know what the values in the mapping mean - or if I have any improvement at all. Does anyone have experience with this or can help me understand what to the numbers in mapping mean - or more specifically how can you tell which numbers are good for optimum performance? I have attached pictures of the software and mapping so you can see what I mean.

Thanks and have a nice day.

I have a Landi Renzo LPG system on my car, and using Landi Renzo Omegas software. After a bad work of a technician the consumption increased a lot and became laggy and jerky. I auto-calibrated it with the software, but I don't know what the values in the mapping mean - or if I have any improvement at all. Does anyone have experience with this or can help me understand what to the numbers in mapping mean - or more specifically how can you tell which numbers are good for optimum performance? I have attached pictures of the software and mapping so you can see what I mean.

Thanks and have a nice day.