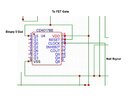

Instead of building a divide by five from individual logic parts, you could use a 74LS390.

This is a dual decade counter, but each decade is done as e divide by 2 and a divide by five.

So you just need to put the pulses in to one of the "B Clock" pins and pulses at one fifth of the frequency will come out of the corresponding "QD" pin.

JimB

This is a dual decade counter, but each decade is done as e divide by 2 and a divide by five.

So you just need to put the pulses in to one of the "B Clock" pins and pulses at one fifth of the frequency will come out of the corresponding "QD" pin.

JimB