Good day everybody,

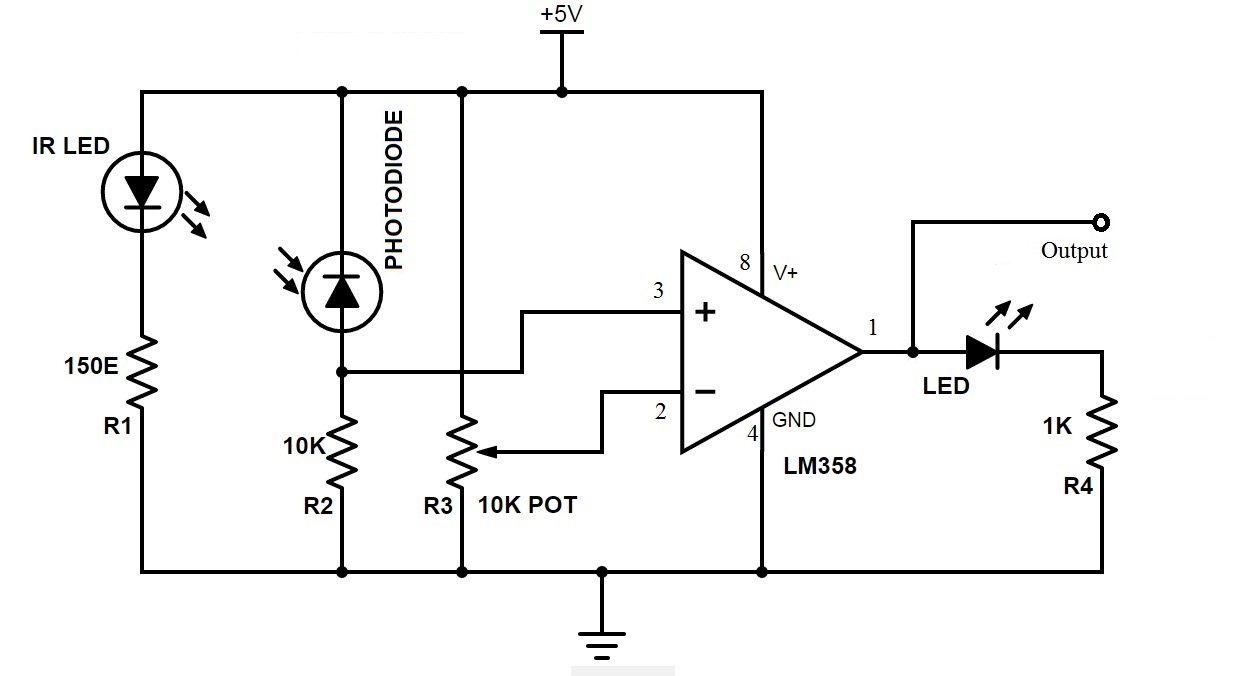

Im currently building a set of line detection sensors using infrared sensors and a comparators which output are connected to a PIC microcontroller for a line following robot. The figure below is a schematic I found online which uses a LM358 OP AMP, however I thought of using 2 LM324N OP AMPs instead of 3 LM358 as its more cost effective.

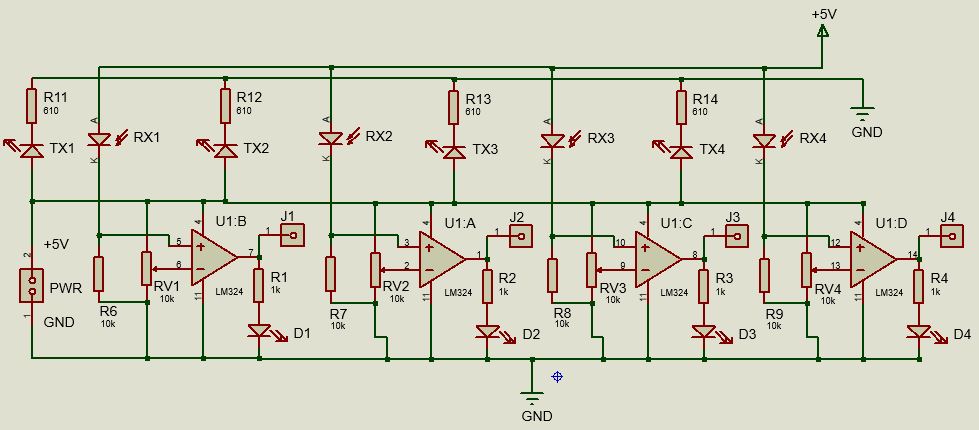

The figure below shows a schematic of 4 sets of IR sensors connected to a LM324N which operating principle is based on the schematic above.

+5V = from LM7805 voltage regulator

Tx = IR transmitter

Rx = IR receiver

R = resistors

RV = 25 multiturn 10k trimmer (3296)

D = LEDs to indicate output high or low

U = LM324N OP AMP

J = single female pin header to connect to input ports of PIC microcontroller

I have built this configuration on a breadboard and generally there are no problems.

However, when I fine tune the circuit to detect the black and white surface at a close distance (2cm) by adjusting the 25 multiturn trimmers, I will encounter a problem. Adjusting 1 or 2 trimmers will not give me any problems but adjusting the 3rd or 4th trimmers will cause the output of the previous 2 sensors to become either LOW or HIGH (opposite value from previous adjustment).

Therefore now Im stuck in a never ending cycle of adjusting the exact value of the trimmer every time I power it and this is not a practical way. I have run out of ideas on how to solve it as I do not know what is the problem.

Any suggestion/ improvements are welcomed

Im currently building a set of line detection sensors using infrared sensors and a comparators which output are connected to a PIC microcontroller for a line following robot. The figure below is a schematic I found online which uses a LM358 OP AMP, however I thought of using 2 LM324N OP AMPs instead of 3 LM358 as its more cost effective.

The figure below shows a schematic of 4 sets of IR sensors connected to a LM324N which operating principle is based on the schematic above.

+5V = from LM7805 voltage regulator

Tx = IR transmitter

Rx = IR receiver

R = resistors

RV = 25 multiturn 10k trimmer (3296)

D = LEDs to indicate output high or low

U = LM324N OP AMP

J = single female pin header to connect to input ports of PIC microcontroller

I have built this configuration on a breadboard and generally there are no problems.

However, when I fine tune the circuit to detect the black and white surface at a close distance (2cm) by adjusting the 25 multiturn trimmers, I will encounter a problem. Adjusting 1 or 2 trimmers will not give me any problems but adjusting the 3rd or 4th trimmers will cause the output of the previous 2 sensors to become either LOW or HIGH (opposite value from previous adjustment).

Therefore now Im stuck in a never ending cycle of adjusting the exact value of the trimmer every time I power it and this is not a practical way. I have run out of ideas on how to solve it as I do not know what is the problem.

Any suggestion/ improvements are welcomed