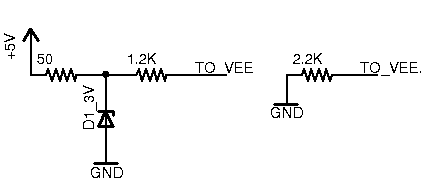

The following are two circuits I came up with. Currently, I'm using a standard HD44780 LCD (1604A). which uses 5V for power and it is connected to other circuitry. All my circuitry is fed through a voltage regulator in a TO-220 type package that delivers a steady 5VDC. I'm also using the circuit pictured on the right to setup the contrast (simply a pull-down resistor).

In the future I will power my circuit with batteries and there will be times when the battery is ready to die. With my current setup, the contrast fades too much when the voltage is below 5V.

The simplest, yet tedius solution that everyone likes is to replace the 2.2K on the right with a potentiometer but the problem with that is I have to change the knob each time the battery state changes which is a pain.

So I thought of using some sort of simplistic voltage regulator circuit that I can easily add to a PCB from parts commonly available.

The internet suggests a circuit setup on the left. I selected the resistor and diode values because I believe based on ohms law and diode voltage drops that I won't burn anything and that the current to the VEE pin is roughly the same.

Then again, maybe I need to include another resistor or something.

Basically I'm trying to make a fixed version of the circuit shown on the right so that the LCD contrast stays at the same level at a much wider range of voltages (at least down to 3V).

How do I modify the circuit on the left to achieve this?

and the diode is a zener.

In the future I will power my circuit with batteries and there will be times when the battery is ready to die. With my current setup, the contrast fades too much when the voltage is below 5V.

The simplest, yet tedius solution that everyone likes is to replace the 2.2K on the right with a potentiometer but the problem with that is I have to change the knob each time the battery state changes which is a pain.

So I thought of using some sort of simplistic voltage regulator circuit that I can easily add to a PCB from parts commonly available.

The internet suggests a circuit setup on the left. I selected the resistor and diode values because I believe based on ohms law and diode voltage drops that I won't burn anything and that the current to the VEE pin is roughly the same.

Then again, maybe I need to include another resistor or something.

Basically I'm trying to make a fixed version of the circuit shown on the right so that the LCD contrast stays at the same level at a much wider range of voltages (at least down to 3V).

How do I modify the circuit on the left to achieve this?

and the diode is a zener.