Not exactly electronics, but I'll bet a lot of people here use laser cutters and may find this useful.

I recently found a community group that offers time on a laser cutter at a very good price. I made a reservation for some time, but was informed that the laser cutter was not working well right now. After some discussion, I offered to help. Long story short, what I didn't know was that it had been more than 6 months since the laser had worked properly, and that any number of people had been wrenching on it. Argh. After a few long days and the realization that nothing was correct, the laser cutter is working again, but needs some additional optimization to cut evenly across the entire 48" x 36" bed.

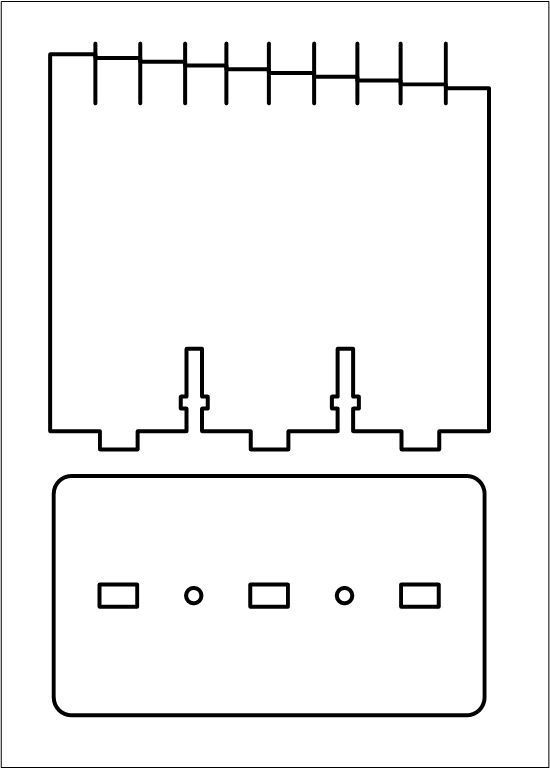

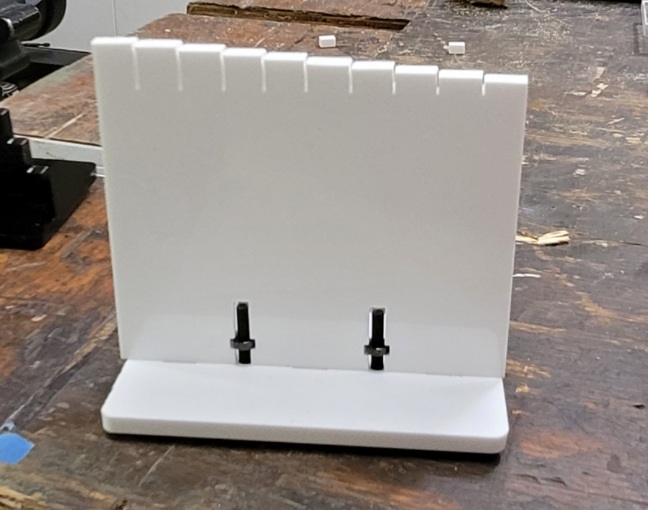

One of those optimizations is getting the bed level. I came up with an idea that has proven very helpful - essentially a (laser-cut) feeler gauge with 1mm steps. Pick a corner and set the bed height so that center step of the gauge will just slip between the bed and the gantry. Then use the gauge at all the corners to measure the variation from that center step to determine where adjustments are needed.

If this looks useful to me, send me a message with your email address and I'll send the svg file.

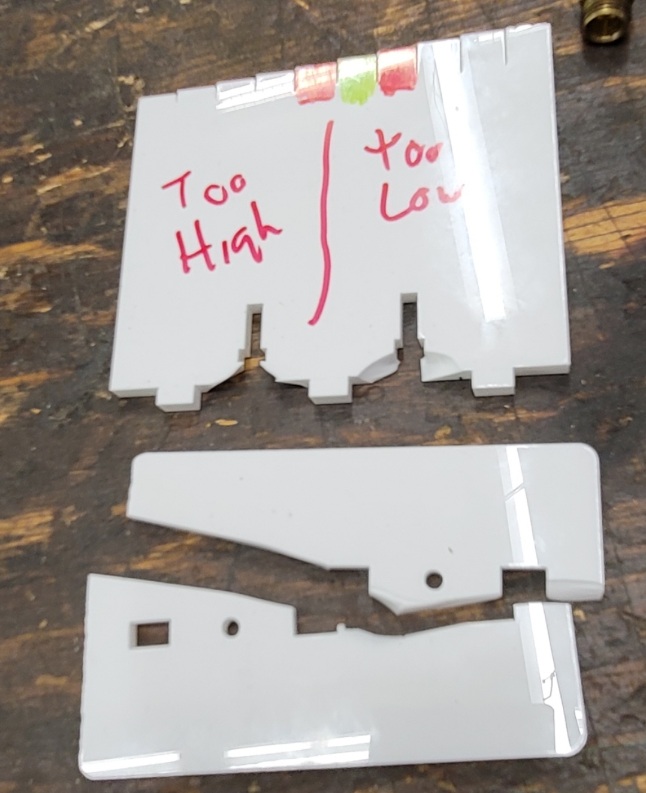

I didn't get a good picture of the tool in use. I colored the center step green with a Sharpie, including the top surface, and the adjacent segments red so it's easy to tell where you're at. The not-so-good picture with the colors shows why you move the gauge out from under the gantry when moving the bed!

I recently found a community group that offers time on a laser cutter at a very good price. I made a reservation for some time, but was informed that the laser cutter was not working well right now. After some discussion, I offered to help. Long story short, what I didn't know was that it had been more than 6 months since the laser had worked properly, and that any number of people had been wrenching on it. Argh. After a few long days and the realization that nothing was correct, the laser cutter is working again, but needs some additional optimization to cut evenly across the entire 48" x 36" bed.

One of those optimizations is getting the bed level. I came up with an idea that has proven very helpful - essentially a (laser-cut) feeler gauge with 1mm steps. Pick a corner and set the bed height so that center step of the gauge will just slip between the bed and the gantry. Then use the gauge at all the corners to measure the variation from that center step to determine where adjustments are needed.

If this looks useful to me, send me a message with your email address and I'll send the svg file.

I didn't get a good picture of the tool in use. I colored the center step green with a Sharpie, including the top surface, and the adjacent segments red so it's easy to tell where you're at. The not-so-good picture with the colors shows why you move the gauge out from under the gantry when moving the bed!