I've starting playing with ESP32 modules and TFT_LCD modules and can see great utility in the combo.

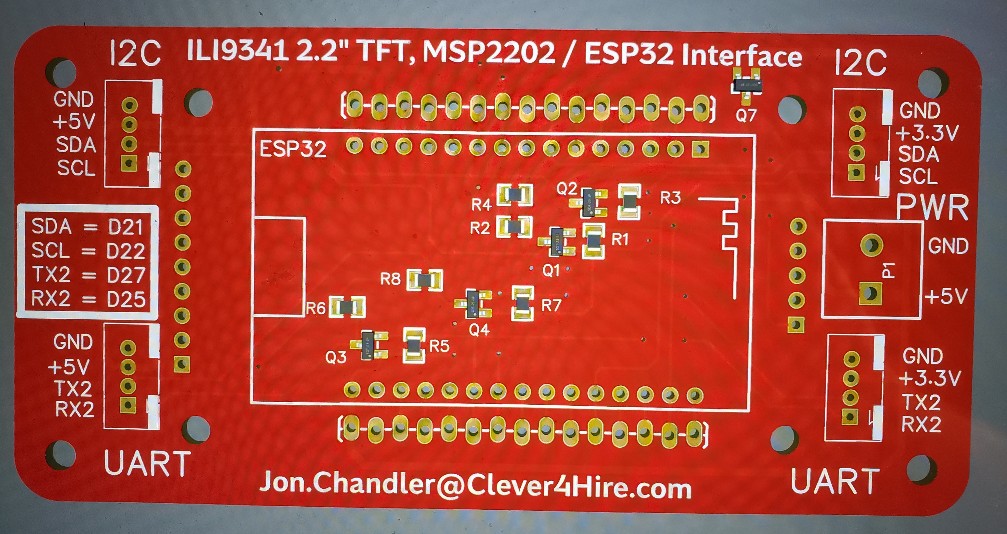

I wanted to build a PCB to marry a 2.2" 320×240 ILI9431 module to an ESP32 dev board and decided to include I2C and UART pins for I/O with level shifting to provide 3.3v and 5v connections. These interfaces are wired out to Seeed Studio's "Grove" connectors and Elecrow's "Crowtail" connectors, which seem to be a somewhat of a standard for sensor and other type modules.

The lever shifters are a simple circuit using N-channel mosfets and a couple resistors per channel. I also included a P-channel mosfet for input power reverse polarity protecrion. The board is pretty simple, with a total of 5 mosfets and 8 resistors. I decided to give JLCPCB's assembly service a try.

For those who haven't heard about this, if you design around their preferred parts, assembly is almost free, as you'll see in a moment. "Basic" parts are common parts that they have loaded on rows and rows of pick&place machines. You can also use a limited number of "extended" parts, which are less common parts the LCSC has access to but which aren't normally loaded on the P&P machines. I designed around "basic" parts, but couldn't find a suitable P-channel mosfet in their basic or extended offerings.

I uploaded my Gerber files, BOM and centroid files to JLCPCB. Here's the price breakdown to have 10 boards fabricated, a stencil made, and the surface mount components soldered to those boards:

¤ Fabrication of 10 pcbs: $5

¤ Engineering fee for assembly: $7

¤ Solderpaste Stencil: $1.50

!¤ Assembly charge: $0,0015 per pad

¤ Component cost total: about $1

The total cost to assemble 10 boards was $10 – a pretty simple circuit, but assmbly worked out to a buck a board.

Oh wait. The cost of assembly pushed the price up to the point where they gave me a discount of $8, so assembly cost me 20 cents per board!

The limitations:

¤ Only green soldermask may be used for assembly

¤ The service covers only surface mount parts that are in their system.

¤ They will assemble one side of the board only.

¤ There is an up charge for "extended" parts.

The solderpaste stencil is cut only for the parts they will install, so the pads for parts you must install are virgin, without any solder left over from the assembly process.

These boards wouldn't have been difficult for me to assemble myself but this low-cost service does open up the possibly of using smaller components than I can deal with.

I will note – I'm just an amazed customer who has received nothing for this endorsement. It's 4am as I type this, so please pardon any typos I've made.

I wanted to build a PCB to marry a 2.2" 320×240 ILI9431 module to an ESP32 dev board and decided to include I2C and UART pins for I/O with level shifting to provide 3.3v and 5v connections. These interfaces are wired out to Seeed Studio's "Grove" connectors and Elecrow's "Crowtail" connectors, which seem to be a somewhat of a standard for sensor and other type modules.

The lever shifters are a simple circuit using N-channel mosfets and a couple resistors per channel. I also included a P-channel mosfet for input power reverse polarity protecrion. The board is pretty simple, with a total of 5 mosfets and 8 resistors. I decided to give JLCPCB's assembly service a try.

For those who haven't heard about this, if you design around their preferred parts, assembly is almost free, as you'll see in a moment. "Basic" parts are common parts that they have loaded on rows and rows of pick&place machines. You can also use a limited number of "extended" parts, which are less common parts the LCSC has access to but which aren't normally loaded on the P&P machines. I designed around "basic" parts, but couldn't find a suitable P-channel mosfet in their basic or extended offerings.

I uploaded my Gerber files, BOM and centroid files to JLCPCB. Here's the price breakdown to have 10 boards fabricated, a stencil made, and the surface mount components soldered to those boards:

¤ Fabrication of 10 pcbs: $5

¤ Engineering fee for assembly: $7

¤ Solderpaste Stencil: $1.50

!¤ Assembly charge: $0,0015 per pad

¤ Component cost total: about $1

The total cost to assemble 10 boards was $10 – a pretty simple circuit, but assmbly worked out to a buck a board.

Oh wait. The cost of assembly pushed the price up to the point where they gave me a discount of $8, so assembly cost me 20 cents per board!

The limitations:

¤ Only green soldermask may be used for assembly

¤ The service covers only surface mount parts that are in their system.

¤ They will assemble one side of the board only.

¤ There is an up charge for "extended" parts.

The solderpaste stencil is cut only for the parts they will install, so the pads for parts you must install are virgin, without any solder left over from the assembly process.

These boards wouldn't have been difficult for me to assemble myself but this low-cost service does open up the possibly of using smaller components than I can deal with.

I will note – I'm just an amazed customer who has received nothing for this endorsement. It's 4am as I type this, so please pardon any typos I've made.

Last edited: