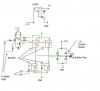

I am trying to use a PIC to control a 12V DC electric motor.

I am having problems with the noise from the motor causing MCU instability.'

The circuit is powered by a 12 V battery with a LM341 Voltage regulator for 5 V power. I already have two seperate ground planes for with a schotky diode seperating them.

Does anybody know a better way of isolating the digital power?

I am having problems with the noise from the motor causing MCU instability.'

The circuit is powered by a 12 V battery with a LM341 Voltage regulator for 5 V power. I already have two seperate ground planes for with a schotky diode seperating them.

Does anybody know a better way of isolating the digital power?