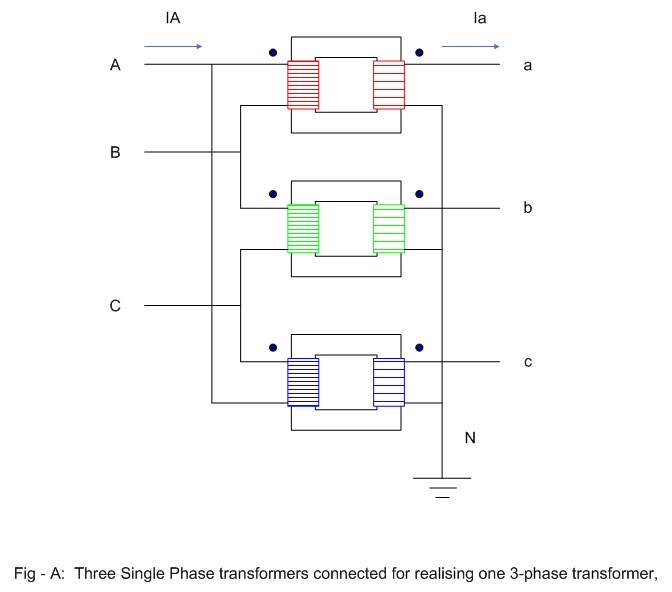

The primary and secondary are wound together on an E I core just like a single phase transformer. It seems to me when L1 gets a sign wave voltage pulse all 3 sections of the transformer should have output voltage. Same for L2 and L3.

I know a 3 phase generator produces 3 separate voltage sign waves 120 degrees apart. If L1, L2, L3 of the transformer all get a voltage wave 120 degrees apart all 3 coils should all 3 have output all at the same time equaling a total of 9 output waves. Apparently there are not 9 voltage pulses so I am trying to understand why?

I bet if I build an E I transformer with 1 primary coil and 3 secondary's, all 3 secondary coils will have output.

I know a 3 phase generator produces 3 separate voltage sign waves 120 degrees apart. If L1, L2, L3 of the transformer all get a voltage wave 120 degrees apart all 3 coils should all 3 have output all at the same time equaling a total of 9 output waves. Apparently there are not 9 voltage pulses so I am trying to understand why?

I bet if I build an E I transformer with 1 primary coil and 3 secondary's, all 3 secondary coils will have output.

Last edited: