*Peter *

New Member

Hey guys...

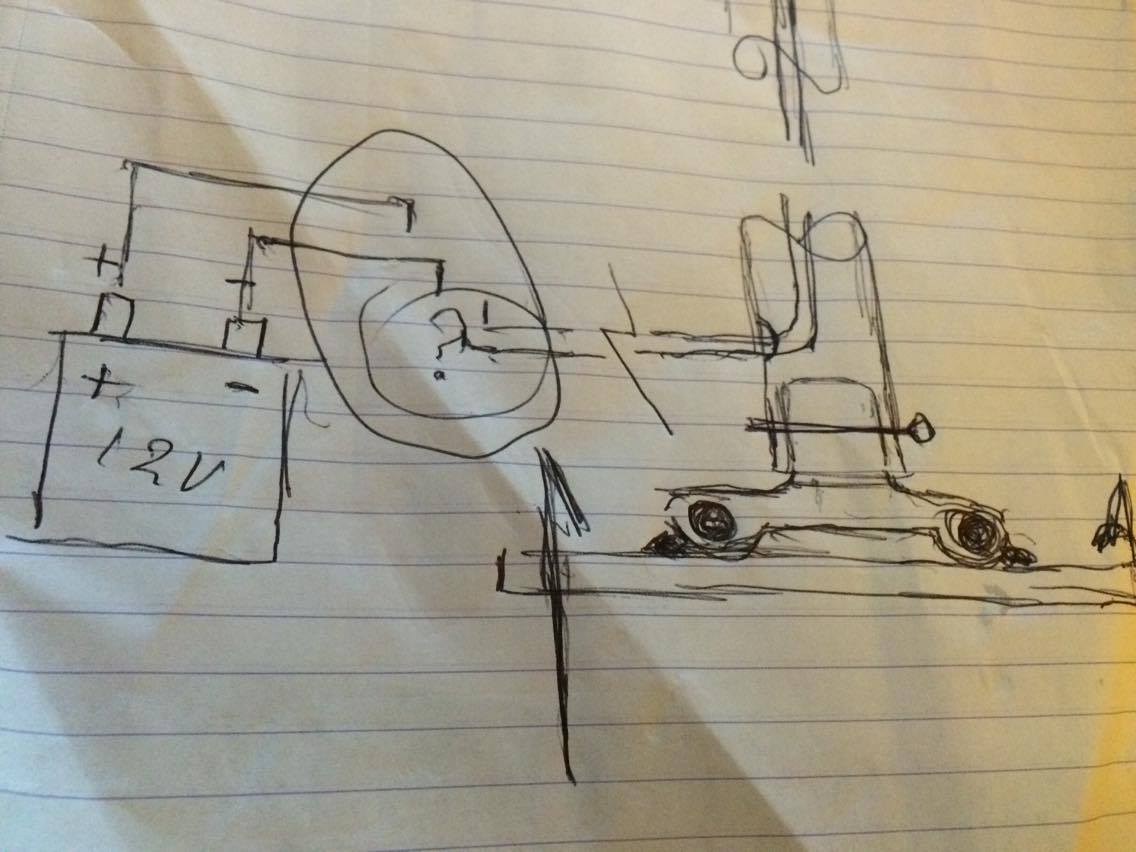

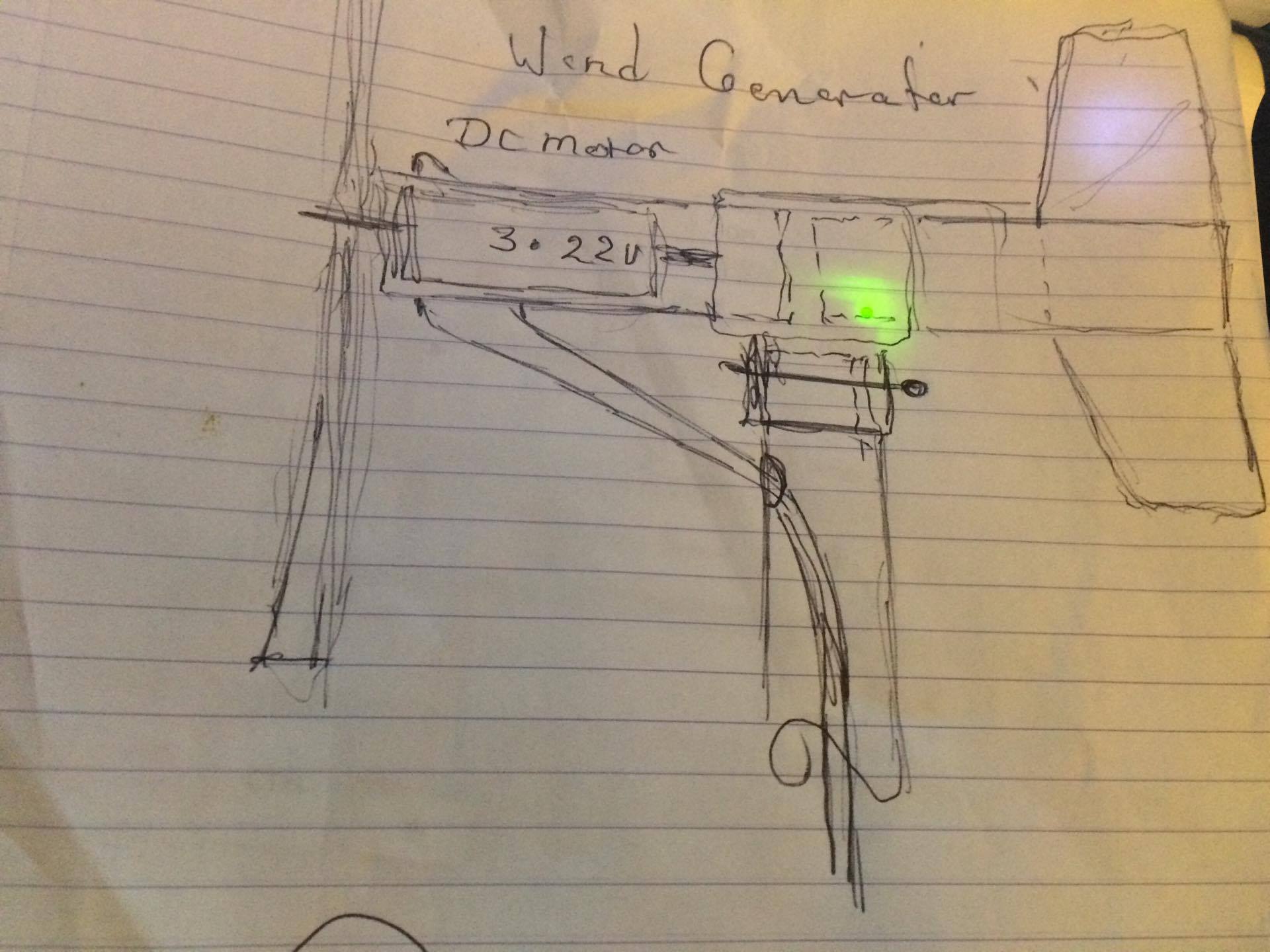

The object of this project is to design and produce a wind generator prototype which can be portability charge batteries (12V) and or other appliances such as a phone. The components I will be using is a DC motor, which has been taken out of a portable fan. This motor has been tested to produce about 3.2V at a decent rpm.

I was thinking, is there any way that this motor can be aligned with other components to charge appliances and batteries as stated above. If this scenario is practical, what other components are needed (If required) and can this setup be sufficient to charge a 12V battery.

Feel free to expand on other ideas on how to make a functional Homemade Wind Generator.

(Note; I am pretty new to this so keep in mind)

Thanks in advanced

The object of this project is to design and produce a wind generator prototype which can be portability charge batteries (12V) and or other appliances such as a phone. The components I will be using is a DC motor, which has been taken out of a portable fan. This motor has been tested to produce about 3.2V at a decent rpm.

I was thinking, is there any way that this motor can be aligned with other components to charge appliances and batteries as stated above. If this scenario is practical, what other components are needed (If required) and can this setup be sufficient to charge a 12V battery.

Feel free to expand on other ideas on how to make a functional Homemade Wind Generator.

(Note; I am pretty new to this so keep in mind)

Thanks in advanced