Hi there,

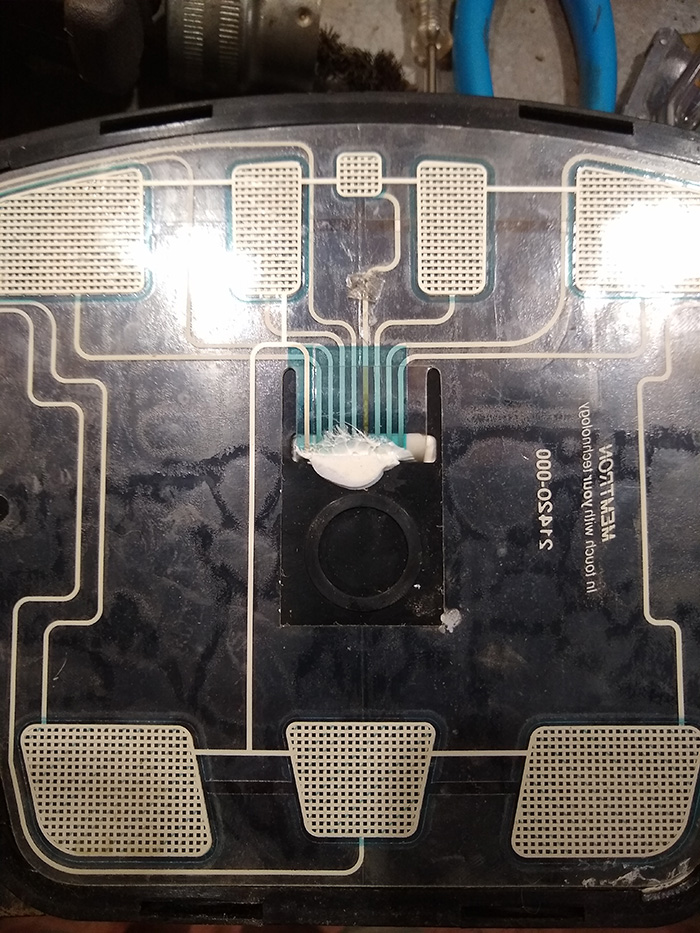

I'm trying to repair the remote control for my trolling motor (it's a motorguide Lazer 370RF). The remote is a foot pad with buttons. Inside is a sheet of plastic film with these little white leads running all over it (see picture). The one that supplies power seems to be burnt out. If you try to scrape off the white stuff, there is no metal inside to solder to.

I'm sure if I knew what this setup was called, I could find a video showing me how to repair or bypass the broken lead. However, no combination of words in Google has given me any luck. Anyone know what it's called, or better yet, how to fix it?

Thanks,

Mitch

I'm trying to repair the remote control for my trolling motor (it's a motorguide Lazer 370RF). The remote is a foot pad with buttons. Inside is a sheet of plastic film with these little white leads running all over it (see picture). The one that supplies power seems to be burnt out. If you try to scrape off the white stuff, there is no metal inside to solder to.

I'm sure if I knew what this setup was called, I could find a video showing me how to repair or bypass the broken lead. However, no combination of words in Google has given me any luck. Anyone know what it's called, or better yet, how to fix it?

Thanks,

Mitch