Hi,

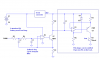

I am trying to design an accurate, stable constant current generator with currents 0.1 mA to 3-4mA. I am trying to do this with digital voltage control PWM. Ideally would have 8 bit to 10 bit resolution, or at least 0.1mA/per %duty cycle. Current load would be 600 ohms to 10 Kohms, so higher voltages need to be generated. Current would be selected in 0.1mA increments, then a PIC would output a corresponding PWM duty cycle. I need this current to remain the same or close despite a change in load. Voltage can vary as necessary.

This will run from battery power 9V or so. Can also run from a wall wart.

I am currently looking at the Fairchild FAN5606 Serial LED Driver with Current-Regulated, Step-Up DC/DC Converter. It has a 5mA limit using only 1 of the DAC inputs. I am not sure what the resolution is on the DAC. Seems like 100 steps?

I would like to use a PIC and a voltage drop resistor as feedback, but I can just send a PWM controlled voltage to the IC.

Any help generating such small currents with these loads is appreciated.

I am trying to design an accurate, stable constant current generator with currents 0.1 mA to 3-4mA. I am trying to do this with digital voltage control PWM. Ideally would have 8 bit to 10 bit resolution, or at least 0.1mA/per %duty cycle. Current load would be 600 ohms to 10 Kohms, so higher voltages need to be generated. Current would be selected in 0.1mA increments, then a PIC would output a corresponding PWM duty cycle. I need this current to remain the same or close despite a change in load. Voltage can vary as necessary.

This will run from battery power 9V or so. Can also run from a wall wart.

I am currently looking at the Fairchild FAN5606 Serial LED Driver with Current-Regulated, Step-Up DC/DC Converter. It has a 5mA limit using only 1 of the DAC inputs. I am not sure what the resolution is on the DAC. Seems like 100 steps?

I would like to use a PIC and a voltage drop resistor as feedback, but I can just send a PWM controlled voltage to the IC.

Any help generating such small currents with these loads is appreciated.

Attachments

Last edited: