Hi makers, first post here!

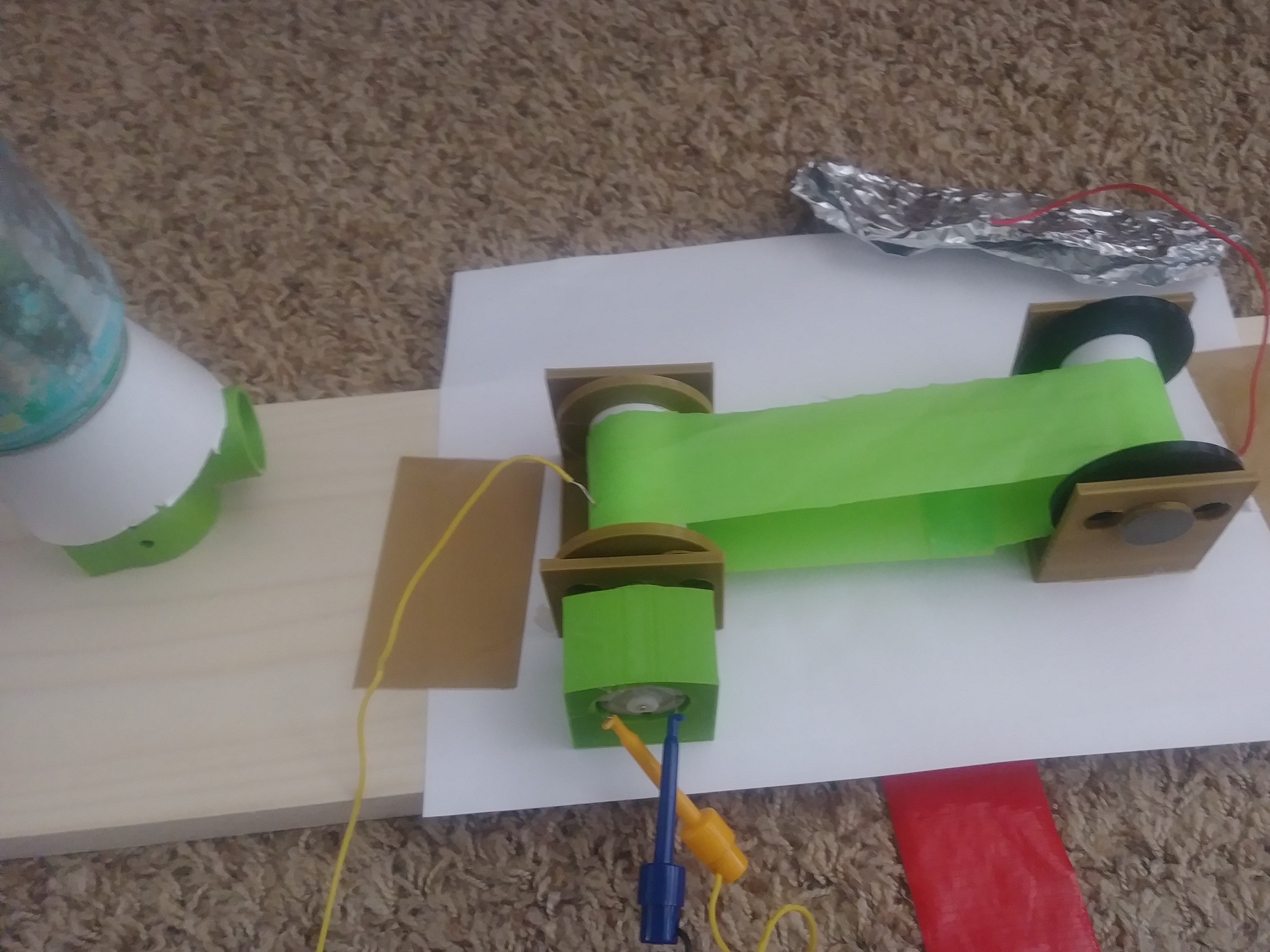

I'm trying to work on a project for a science exhibition at school. I want to make a van de graaff generator using 3D printed parts for the base. I'm just trying to get a working version, but I'm having some troubles.

Build:

There are a bunch of different ways to make it, but I'm basing it loosely on this

He uses an elastic band and PVC pipes, which is what I'm doing. I made rollers and cut the band into shape. I attached a small motor to one roller, and have ground and charging wires. I'm using an empty soda can for the collector of charges, and I was told the ground could be something simple like an aluminum foil or metal bar.

Problem:

In all the videos, it only takes a few cranks before there is enough charge to get strips of paper to move away from each other, and large sparks can fly out if you hold your finger close to the metal ball. In my device, I'm lucky to get even a small spark, and not consistently.

Clarifications:

-There is good connection between the wires and their endpoints (ground or the soda can)

-We live in a desert, so humidity isn't an issue

-When the ground and charging wire were hooked to a capacitor with a voltmeter, the voltmeter showed that there was a slight charge being built up, but it took ~10 seconds of running to motor to get to 3 volts. It also bled out fairly quickly.

I've attached an image (final will be 100% 3D printed but this is a placeholder). Please let me know what could be wrong.

Thanks

-Shokker

I'm trying to work on a project for a science exhibition at school. I want to make a van de graaff generator using 3D printed parts for the base. I'm just trying to get a working version, but I'm having some troubles.

Build:

There are a bunch of different ways to make it, but I'm basing it loosely on this

He uses an elastic band and PVC pipes, which is what I'm doing. I made rollers and cut the band into shape. I attached a small motor to one roller, and have ground and charging wires. I'm using an empty soda can for the collector of charges, and I was told the ground could be something simple like an aluminum foil or metal bar.

Problem:

In all the videos, it only takes a few cranks before there is enough charge to get strips of paper to move away from each other, and large sparks can fly out if you hold your finger close to the metal ball. In my device, I'm lucky to get even a small spark, and not consistently.

Clarifications:

-There is good connection between the wires and their endpoints (ground or the soda can)

-We live in a desert, so humidity isn't an issue

-When the ground and charging wire were hooked to a capacitor with a voltmeter, the voltmeter showed that there was a slight charge being built up, but it took ~10 seconds of running to motor to get to 3 volts. It also bled out fairly quickly.

I've attached an image (final will be 100% 3D printed but this is a placeholder). Please let me know what could be wrong.

Thanks

-Shokker