Buzzed Aldrin

New Member

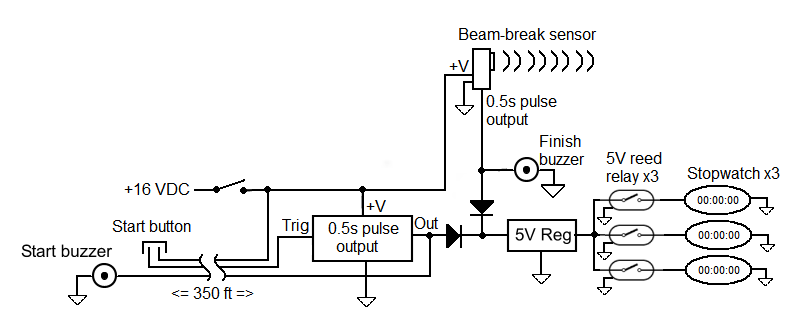

The system shown is to time an athlete running a sprint. At the starting end, the runner releases the start button to create a 0.5 sec pulse to the reed relays to start the digital stopwatches.

When the runner breaks the light beam at the finish line, the photo sensor outputs a 0.5 sec pulse to stop the timing.

3 stopwatches are used to verify accuracy, i.e. if all stopwatches agree, then I consider the system to be accurate.

PROBLEM: The stopwatches often don't agree -- The displays can be different by up to 0.04 seconds (40 ms).

=> I would like to know what could cause the different stopwatch indications?

Additional info:

1. At first I thought the problem was due to a transient current imbalance between the inputs to the 3 relays causing them to not operate the stopwatches at the same time, but this would cause a repeatable time difference affecting the same stopwatch(es), no? The time differences occur randomly -- any of the stopwatches can be faster or slower, from zero to +/-0.04 seconds, than the other 2 stopwatches for any timing instance.

2. I can tell that the stopwatches do not start / stop at the same instant, based on mis-synchronized "beep" sound, so the problem is not with the stopwatches themselves. They all use the same basic chip and circuitry, which is accurate to about 3 sec per day which is much less than the time differences.

3. Response time of the reed relays is only 0.5 ms, also much less than the time differences, so the relays are probably not an issue.

Any help appreciated!

When the runner breaks the light beam at the finish line, the photo sensor outputs a 0.5 sec pulse to stop the timing.

3 stopwatches are used to verify accuracy, i.e. if all stopwatches agree, then I consider the system to be accurate.

PROBLEM: The stopwatches often don't agree -- The displays can be different by up to 0.04 seconds (40 ms).

=> I would like to know what could cause the different stopwatch indications?

Additional info:

1. At first I thought the problem was due to a transient current imbalance between the inputs to the 3 relays causing them to not operate the stopwatches at the same time, but this would cause a repeatable time difference affecting the same stopwatch(es), no? The time differences occur randomly -- any of the stopwatches can be faster or slower, from zero to +/-0.04 seconds, than the other 2 stopwatches for any timing instance.

2. I can tell that the stopwatches do not start / stop at the same instant, based on mis-synchronized "beep" sound, so the problem is not with the stopwatches themselves. They all use the same basic chip and circuitry, which is accurate to about 3 sec per day which is much less than the time differences.

3. Response time of the reed relays is only 0.5 ms, also much less than the time differences, so the relays are probably not an issue.

Any help appreciated!