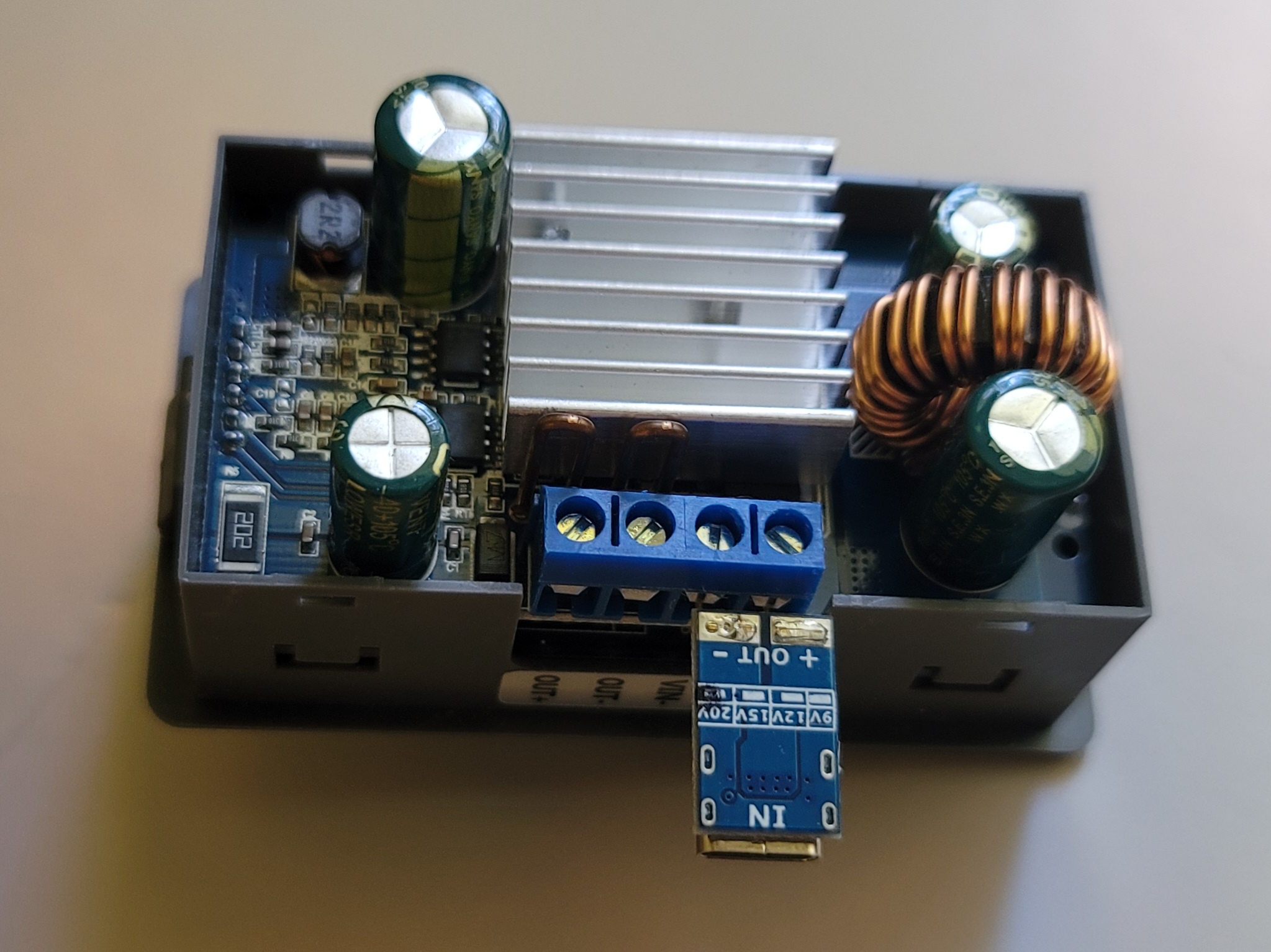

I often find a small portable power supply would be very handy. I had this idea, which furthers Externet 's disgust of the prostitution of USB power supplies, to connect a USB C PD 20 volt trigger to one of the common buck/boost modules that have a display and all the whistles (adjustable voltage, current, power consumption tracking).

As I had a 20 volt USB C PD trigger (negotiates with the power supply to give the desired voltage) with header pins soldered on, it was simple enough to test. The PD trigger is barely larger than a USB C connector and in fact are available built into a USB cable.

I connected the trigger to the module and connected it to my phone charger which was convenient. Instant success, with the output voltage range adjustable from 0.6 – about 20 volts. Awesome!

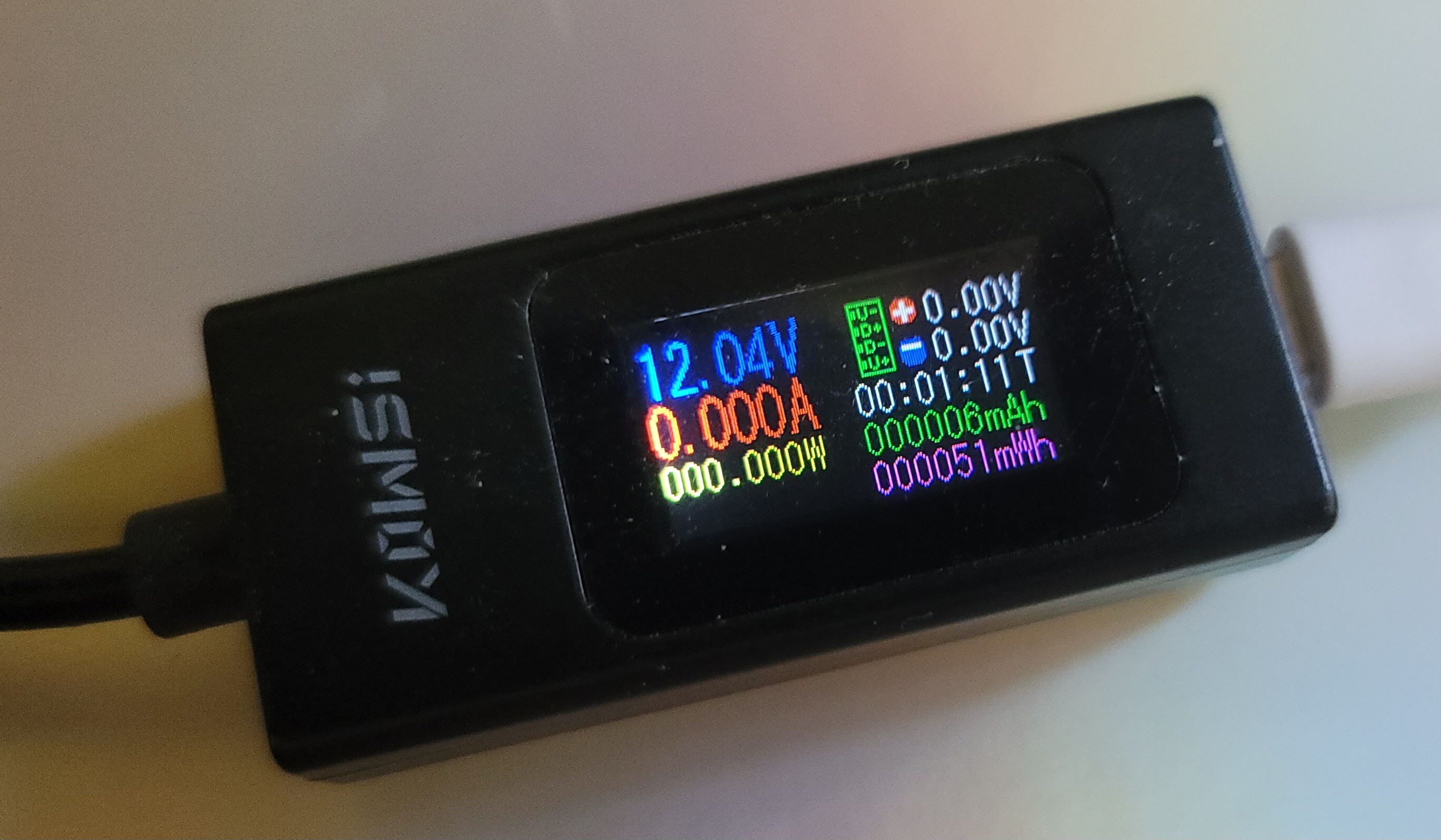

My phone charger is not USB C PD, but has QC high rate charging, which has the potential to supply 9 volts. I put my USB meter in line, and found only 5 volts being supplied to the module, which was expected as the charger is not USB C PD.

Upwards and onwards. Connected a USB C PD charger to the trigger and module, and the module was happy to provide its full range of 30 volts.

The USB C PD charger I tested with can supply 15 volts maximum, so the trigger and charger negotiated to 12 volts. Beautiful. So this 3" × 2" × 1.5" power supply module can be connected to any handy USB charger to serve my needs. That's pretty cool.

The power supply module shown here is an XY-SK35 but many variations are available in the same package. This one is a little low on the features list.

As I had a 20 volt USB C PD trigger (negotiates with the power supply to give the desired voltage) with header pins soldered on, it was simple enough to test. The PD trigger is barely larger than a USB C connector and in fact are available built into a USB cable.

I connected the trigger to the module and connected it to my phone charger which was convenient. Instant success, with the output voltage range adjustable from 0.6 – about 20 volts. Awesome!

My phone charger is not USB C PD, but has QC high rate charging, which has the potential to supply 9 volts. I put my USB meter in line, and found only 5 volts being supplied to the module, which was expected as the charger is not USB C PD.

Upwards and onwards. Connected a USB C PD charger to the trigger and module, and the module was happy to provide its full range of 30 volts.

The USB C PD charger I tested with can supply 15 volts maximum, so the trigger and charger negotiated to 12 volts. Beautiful. So this 3" × 2" × 1.5" power supply module can be connected to any handy USB charger to serve my needs. That's pretty cool.

The power supply module shown here is an XY-SK35 but many variations are available in the same package. This one is a little low on the features list.