That looks pretty good. Just make sure you have the tap between the two windings.

yes i have the tap. ill post my further progress with the driver soon.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

That looks pretty good. Just make sure you have the tap between the two windings.

the self wound primary isnt working. i tried it with the 2n3055 driver also, besides the zvs driver. it isnt giving me any HV output. i have put 10 turns of 2mm thick Cu wire, the pic of which i had already posted. can su1 tell me whats wrong with it?

The first thing that comes to mind is that you may be using un-insulated wire. The wire would have to be insulated for this to work.

It would help to have a photo or two of your setup, as well.

Der Strom

im using insulated wire. and yes i have rubbed off the insulation at the ends to connect with driver. i got 0.8 milli volts as the "high voltage output" with the 2n3055 driver and 0.0 mV with the zvs driver. photo already posted in page 2, and its simple winding, in the same direction, in single layer, as one should wind.

moreover, ppl say we are supposed to use thick wire. and then they say primary coil resistance is 1 ohm???? im getting 0.0 ohm (my multimeter doesnt hv milliohms ) of the self wound primary. is the 2mm Cu wire too thick for it?

Okay, that's a good start.

When I suggested a photo, I meant the entire setup, not just the transformer.

Also, did you make any substitutions in the circuits? Different transistors, perhaps, or a different power supply?

2mm copper wire should be ok. What exactly is your power supply? The circuit calls for 10-40 Volts, and more than 10 Amps. If I remember right, you're using a 9 volt, 800mA wall adapter? This will not be sufficient. The circuit would work best with something like a car battery, capable of supplying 12 volts, usually at a few hundred amps. See if you can find one of these.

Good luck!

Der Strom

i also both the non mosfet and the zvs drivers with 12 V batt. capable of giving 1.4 amps.... and i got almost 0v as high voltage in both cases. and i ended up frying up my 2n3055 ....

well..... i tried reversing the winding direction, changed polarities, but still nothing. maybe this FBT works only with the inbuilt primary.... its construction is special sumhow, maybe, or too worse in other words.

i called in a TV repairman, but imo, he is just a repairman, nothing else. at first he said that theres no way to make the FBT work without the TV circuit!anyways, i hv only 3 days left to complete this project. i needed some 3rd party's opinion.... some of them are:

- while the FBT is detatched from the circuit, he was getting 0 volts in multimeter when the leads r connected either to the primary terminals from the drains of the mosfets, or to primary and centre tap. he said that this shouldnt be happening. do u think this is expected? since he was connecting only 2 leads at a time, would it make a closed circuit?

- he said that the centre tap is already there in the FBT pins, and suggested to use pin 9 as the centre tap. can i really use it? (refer to post 1 for readings)

- he says we hv to provide minimum 100v DC to the primary or else it wont work.

im getting 0.5 mm sparkfrom a 12V 1A supply.

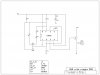

in the circuit, im using a ceramic cap of 1 nf (am i supposed to use electrolytic?) , a 100k preset in place of 50k (but i think since its a preset, it can be brought down to 50k by rotating) and irf540 mosfet. the rest are the same components as mentioned in the circuit. im using 1 watt resistors. anything wrong in these?

1nf cap is awful low? Its a 555 circuit and lower the capacitor value, higher the frequency.

well, I replaced the 1nf with a 10pf just out of curiosity. And now I got 3mm sparks..... But I heard no whizz, I.e.the flyback was running in ultrasonic freq. And the current drawn in idle state was still 0.08A, but during sparks, it reached 5.5A.........what conclusion do u draw from the circuit and the "crappy special" flyback?

.fyi, 3mm sparks isn't enough for my purpose. I need to make a lifter fly for the project due on monday

i chked ur circuit. the circuit i hv made already has adjustable duty cycle- thats what the 100k variable resistor is for.

well, the final option for the lifter is the tv itself, but that wont fetch much marks. a self made circuit is more imperssive