Hi Guys

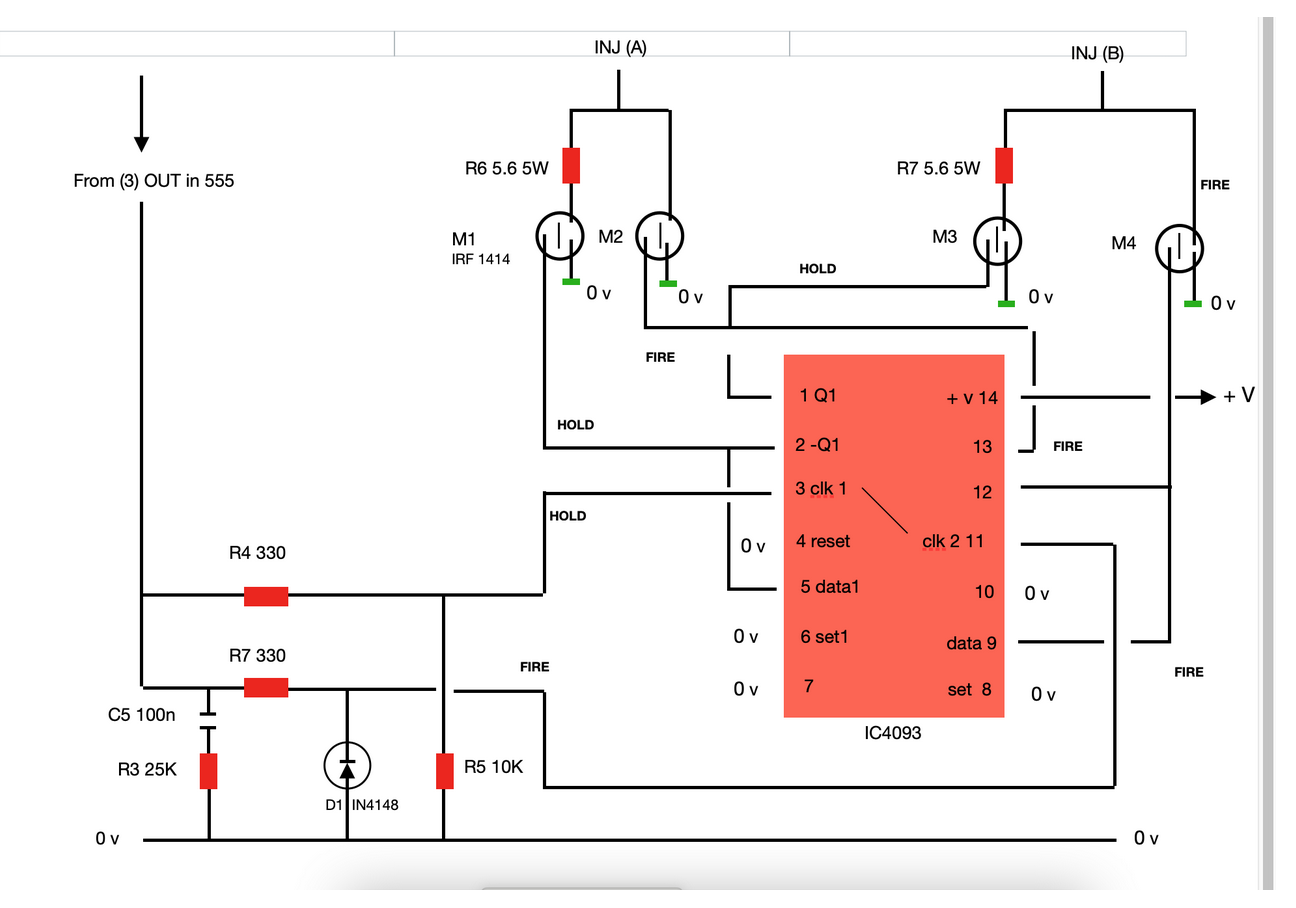

Would someone kindly look at this diagram and tell me if its right? The idea is, for each injector (think v. low inductance coil), a fast pulse is overlapped by a slower pulse, then next time, the other injector is treated the same, and back again. The fast pulse is a bigger current to get a fast response (FIRE), but the slower dwell (HOLD) with a lower current allows a quick mechanical reversal. Thank you! Malc

Would someone kindly look at this diagram and tell me if its right? The idea is, for each injector (think v. low inductance coil), a fast pulse is overlapped by a slower pulse, then next time, the other injector is treated the same, and back again. The fast pulse is a bigger current to get a fast response (FIRE), but the slower dwell (HOLD) with a lower current allows a quick mechanical reversal. Thank you! Malc