Slickgsxr5

New Member

If anyone can help me figure this out I might be able to move on with my life!

Ok so I decided as my first project I wanted to replicate and tweak (click here) This design of board and make it my own.

While the finished product "worked" I ran into issues, one in particular i can't seem to rectify. I do fully realize some of the issues that came up were my fault by adding components and changing the original design. Again the original design is 10+ years old and I realize there are readily available professional built systems to buy.

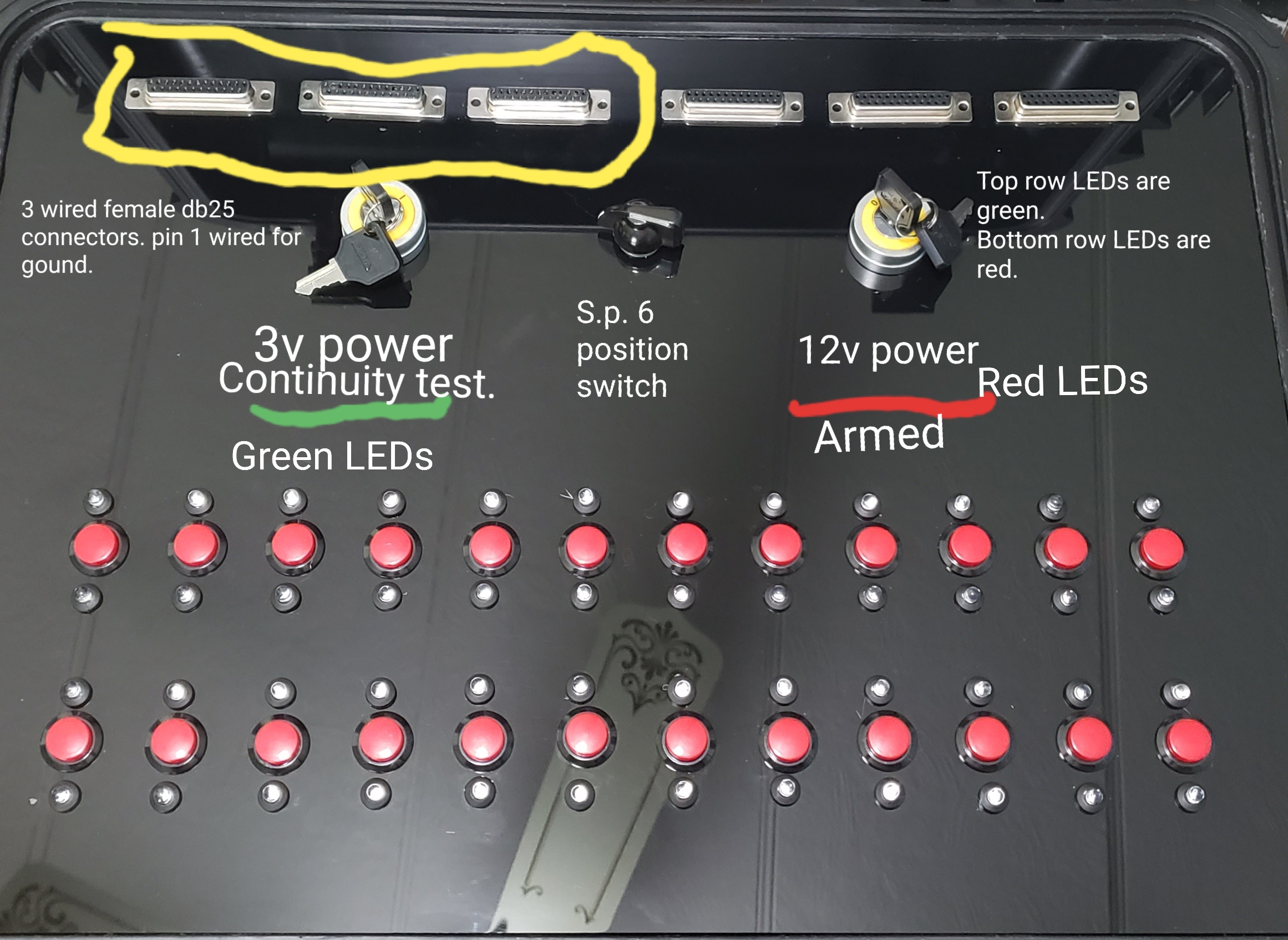

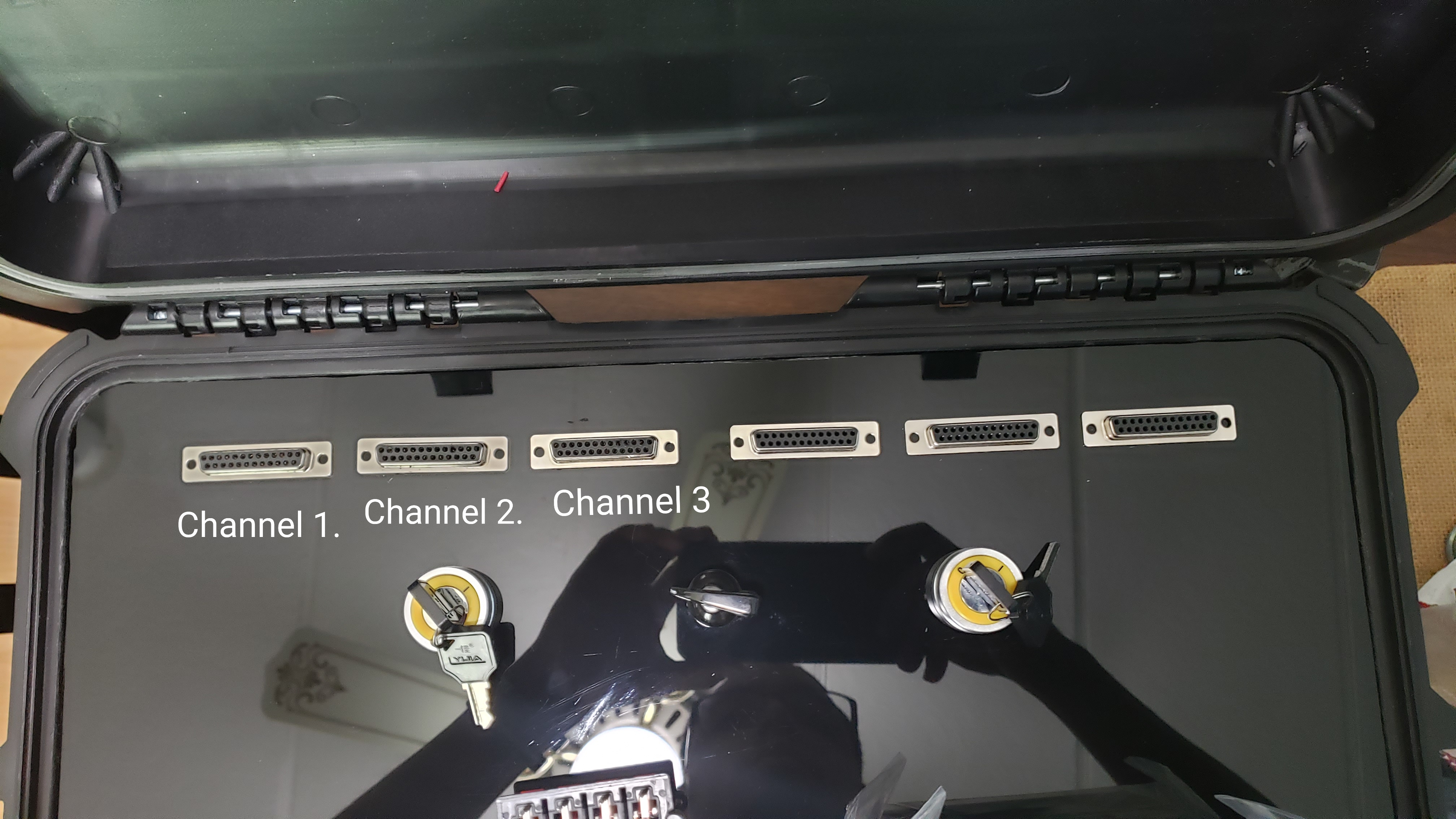

I first only wire up 3 of the 6 Db25 connections as I only possibly needed 3 remote boxes at this time. It also keeps the mess of wires to a minimum.

Instead of bundling a mess of wires for the 24 cue buttons, I daisy chained them together. These buttons connect to only the 12v key switch.

Not part of the original design, I decided to add red LEDs as part of the 12v circuit. Both the red and green LEDs came wired with these resistors...

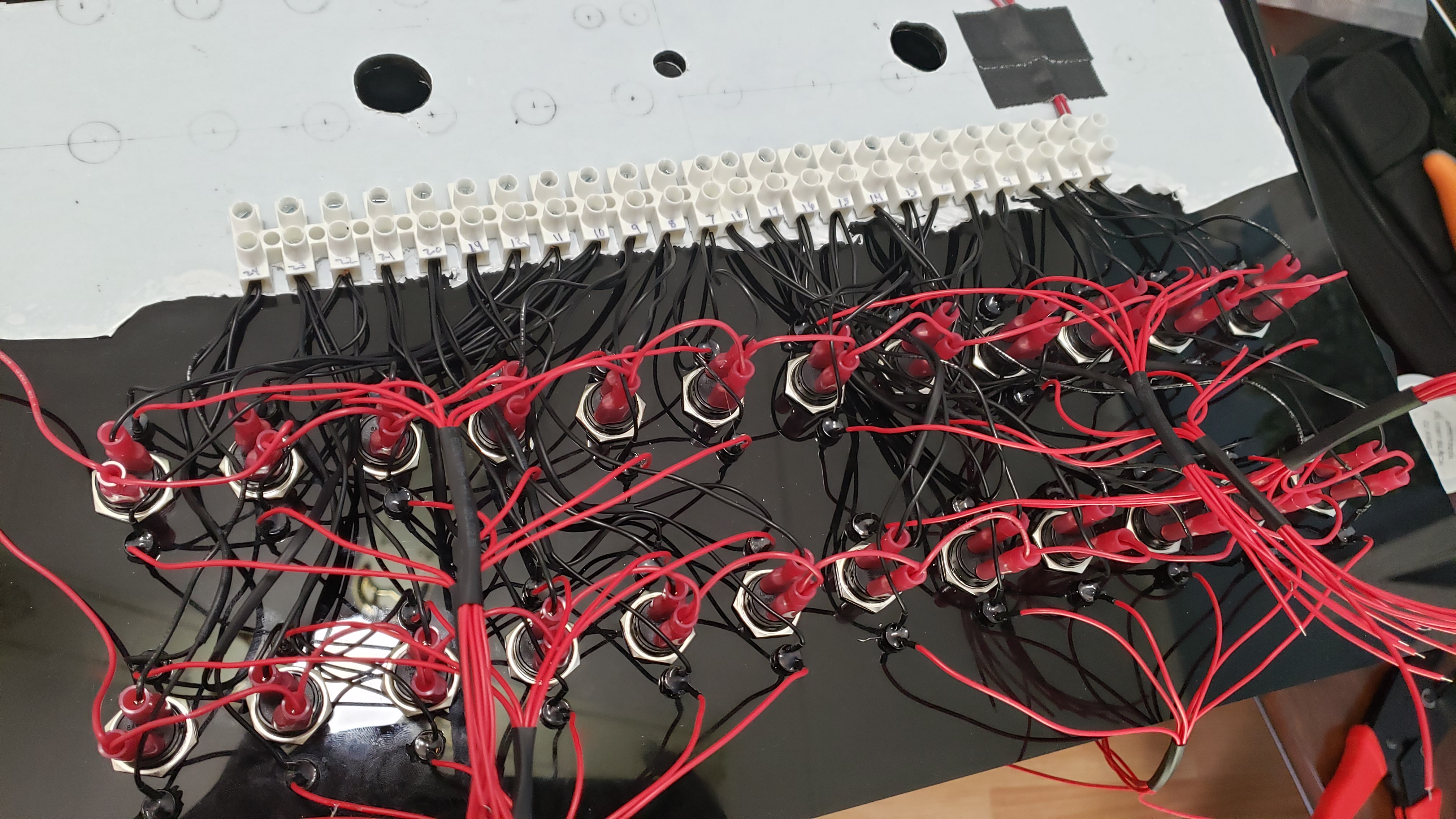

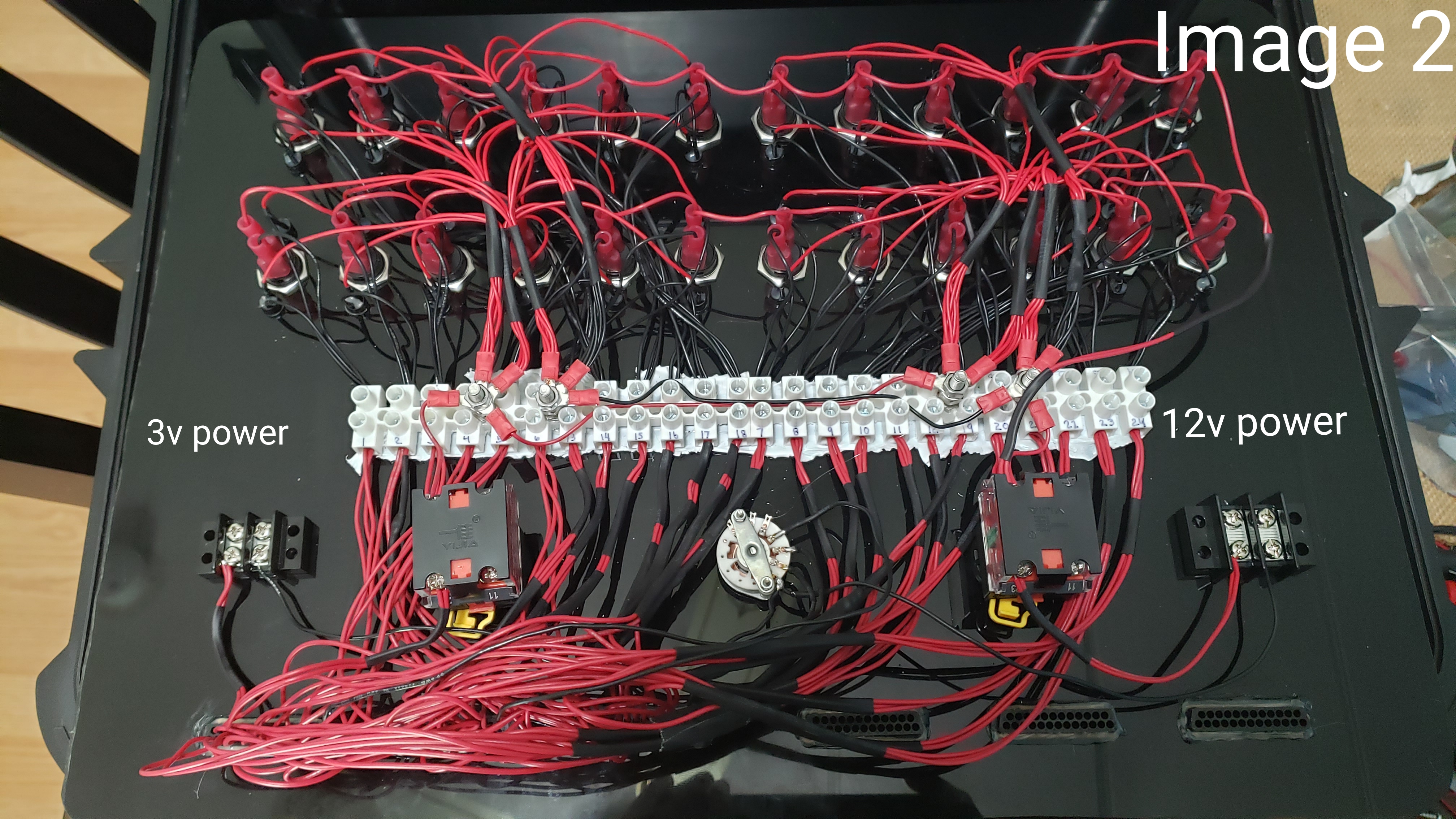

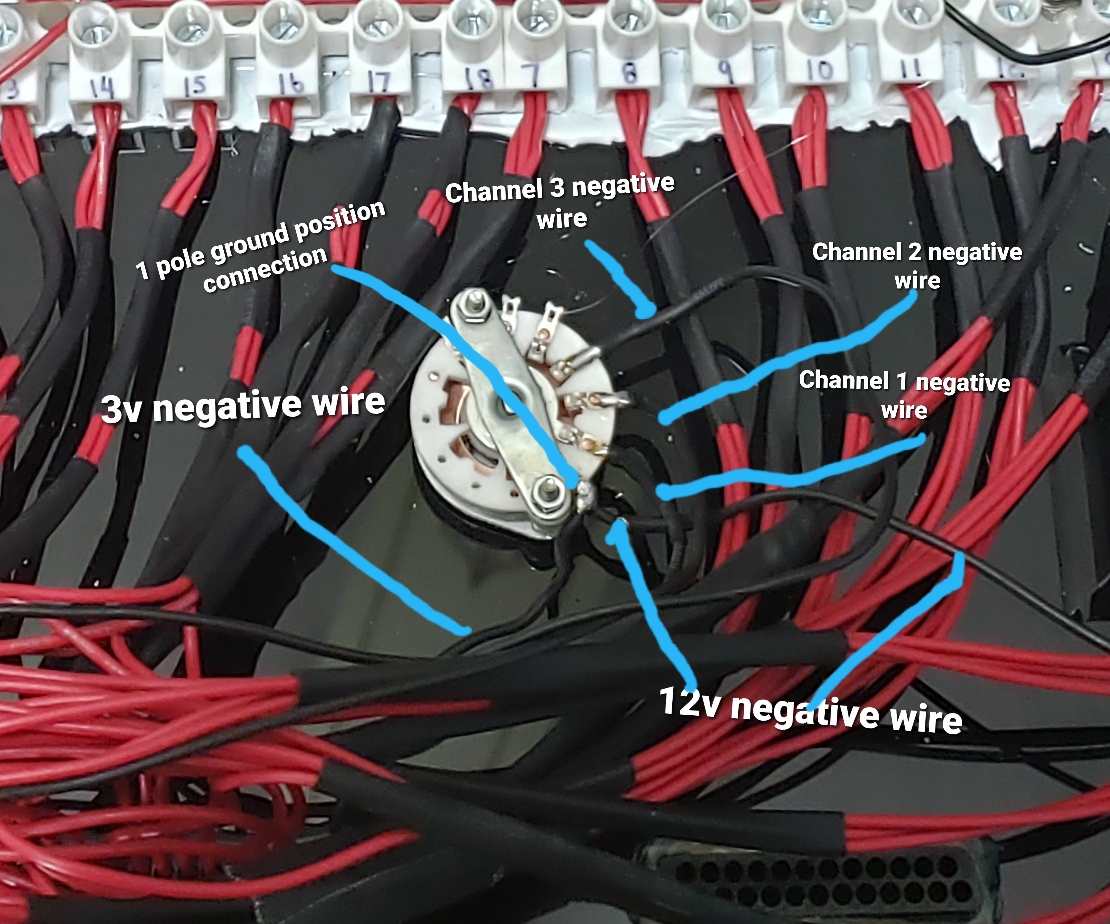

I connected the negative wires from the green LEDs, red LEDs and the cue button to one side of the terminal strip. This decision introduced the first issue I ran into after full assembly.

Only when the 12v key switch was turned on and I jumped the ground pin with each cue to complete the circuit, not only did the red led light up, but also very faintly lit up the green led on each cue when tested. Figuring that the 12v was enough to backfeed the green led with enough power to dimly light it. (Which to me is strange...LEDs only work one way from +to- right? The positive wires from the green LEDs are ONLY connected to the 3v key switch.) I jumped the negative wires from the green LEDs to the other side of the terminal strip. Which for the most part worked. It also worked on each channel as well.

When I finished one of the remote boxes I connected, jumped each cue terminal and tested for good continuity and that every cue matched with how the box was wired as to what cue LEDs lit up on the control board AND tested an actual igniter, I was satisfied everything was in order. It wasn't until I was out in the field connecting the fireworks to the igniters to the remote boxes till I noticed a HUGE problem.

I DON'T KNOW HOW TO FIX PROBLEM 2....

Problem 2: If ONE remote box is connected say channel 1,2 or 3....everything works exactly how it should. Press cue 1 button - cue 1 igniter fires and lights the firework. Just like it should. The problem arises when MORE than ONE remote box is connected to the system.

If say remote box on channel 1 has all 24 cues filled and I connect the empty remote box to channel 2 then switch to channel 2, naturally the circuit is still open as there is nothing connected. As soon as ONE cue is connected and closes the circuit, all 24 cue light up as if they were ALL connected to igniters.

Here's a video showing the problem.

Ok so I decided as my first project I wanted to replicate and tweak (click here) This design of board and make it my own.

While the finished product "worked" I ran into issues, one in particular i can't seem to rectify. I do fully realize some of the issues that came up were my fault by adding components and changing the original design. Again the original design is 10+ years old and I realize there are readily available professional built systems to buy.

I first only wire up 3 of the 6 Db25 connections as I only possibly needed 3 remote boxes at this time. It also keeps the mess of wires to a minimum.

Instead of bundling a mess of wires for the 24 cue buttons, I daisy chained them together. These buttons connect to only the 12v key switch.

Not part of the original design, I decided to add red LEDs as part of the 12v circuit. Both the red and green LEDs came wired with these resistors...

I connected the negative wires from the green LEDs, red LEDs and the cue button to one side of the terminal strip. This decision introduced the first issue I ran into after full assembly.

Only when the 12v key switch was turned on and I jumped the ground pin with each cue to complete the circuit, not only did the red led light up, but also very faintly lit up the green led on each cue when tested. Figuring that the 12v was enough to backfeed the green led with enough power to dimly light it. (Which to me is strange...LEDs only work one way from +to- right? The positive wires from the green LEDs are ONLY connected to the 3v key switch.) I jumped the negative wires from the green LEDs to the other side of the terminal strip. Which for the most part worked. It also worked on each channel as well.

When I finished one of the remote boxes I connected, jumped each cue terminal and tested for good continuity and that every cue matched with how the box was wired as to what cue LEDs lit up on the control board AND tested an actual igniter, I was satisfied everything was in order. It wasn't until I was out in the field connecting the fireworks to the igniters to the remote boxes till I noticed a HUGE problem.

I DON'T KNOW HOW TO FIX PROBLEM 2....

Problem 2: If ONE remote box is connected say channel 1,2 or 3....everything works exactly how it should. Press cue 1 button - cue 1 igniter fires and lights the firework. Just like it should. The problem arises when MORE than ONE remote box is connected to the system.

If say remote box on channel 1 has all 24 cues filled and I connect the empty remote box to channel 2 then switch to channel 2, naturally the circuit is still open as there is nothing connected. As soon as ONE cue is connected and closes the circuit, all 24 cue light up as if they were ALL connected to igniters.

Here's a video showing the problem.