Shadow_warrior

Member

Hello people!

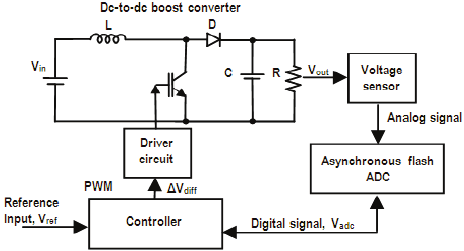

I am using a Voltage Sensor to sense dc output voltage of a DC/DC converter and then this sensed voltage is picked up by ADC for Closed loop operation.

I have following doubts

I am using a Voltage Sensor to sense dc output voltage of a DC/DC converter and then this sensed voltage is picked up by ADC for Closed loop operation.

I have following doubts

- Since, there will be some ripple in Output Voltage, do i need some sort of filter before ADC?

- Will a low pass filter sufficent? If yes What should be its cut-off frequency?

- What qualities should I look in the op-amp or which op-amp will be sufficient if my switching frequency is 10KHz?