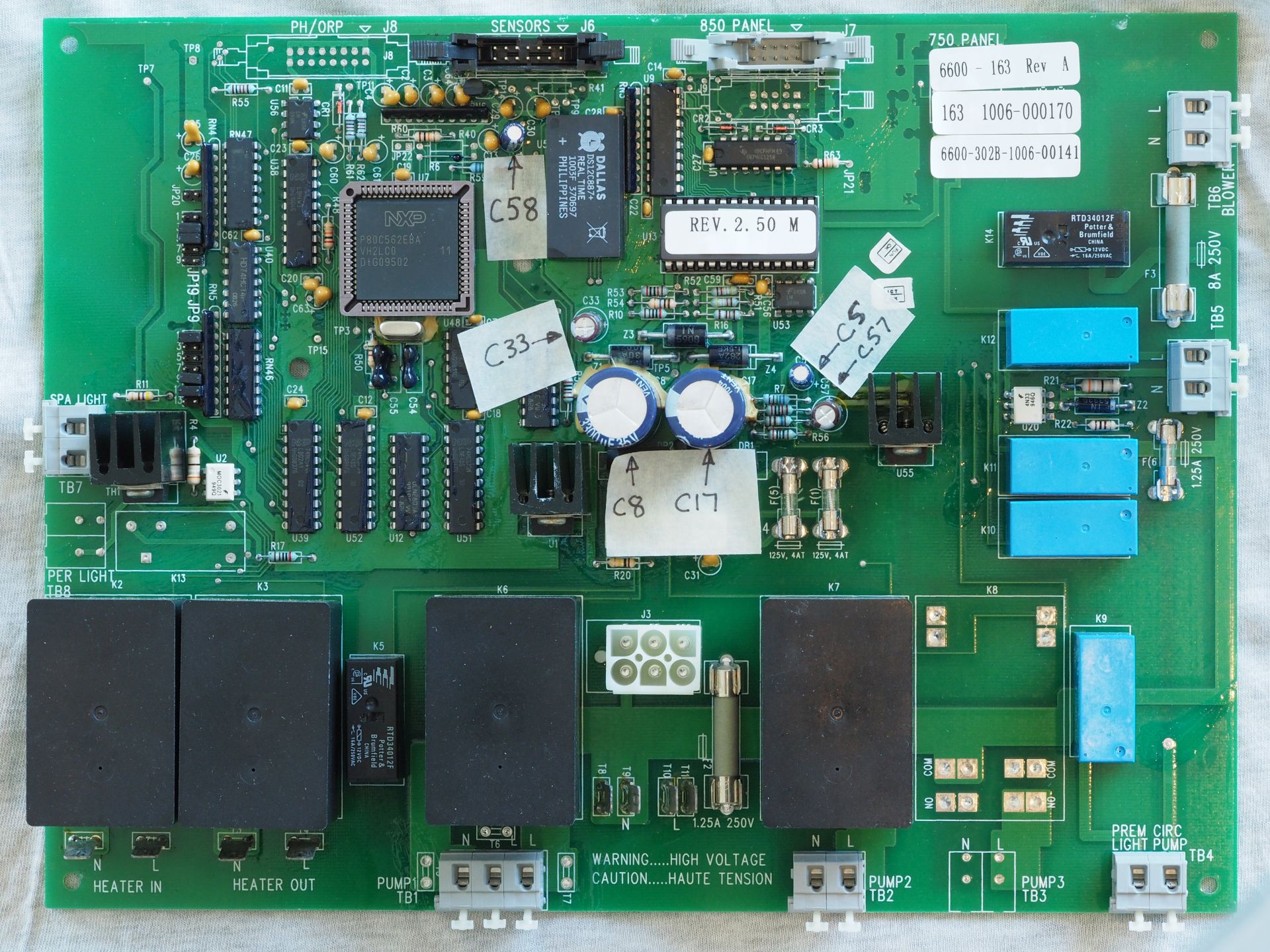

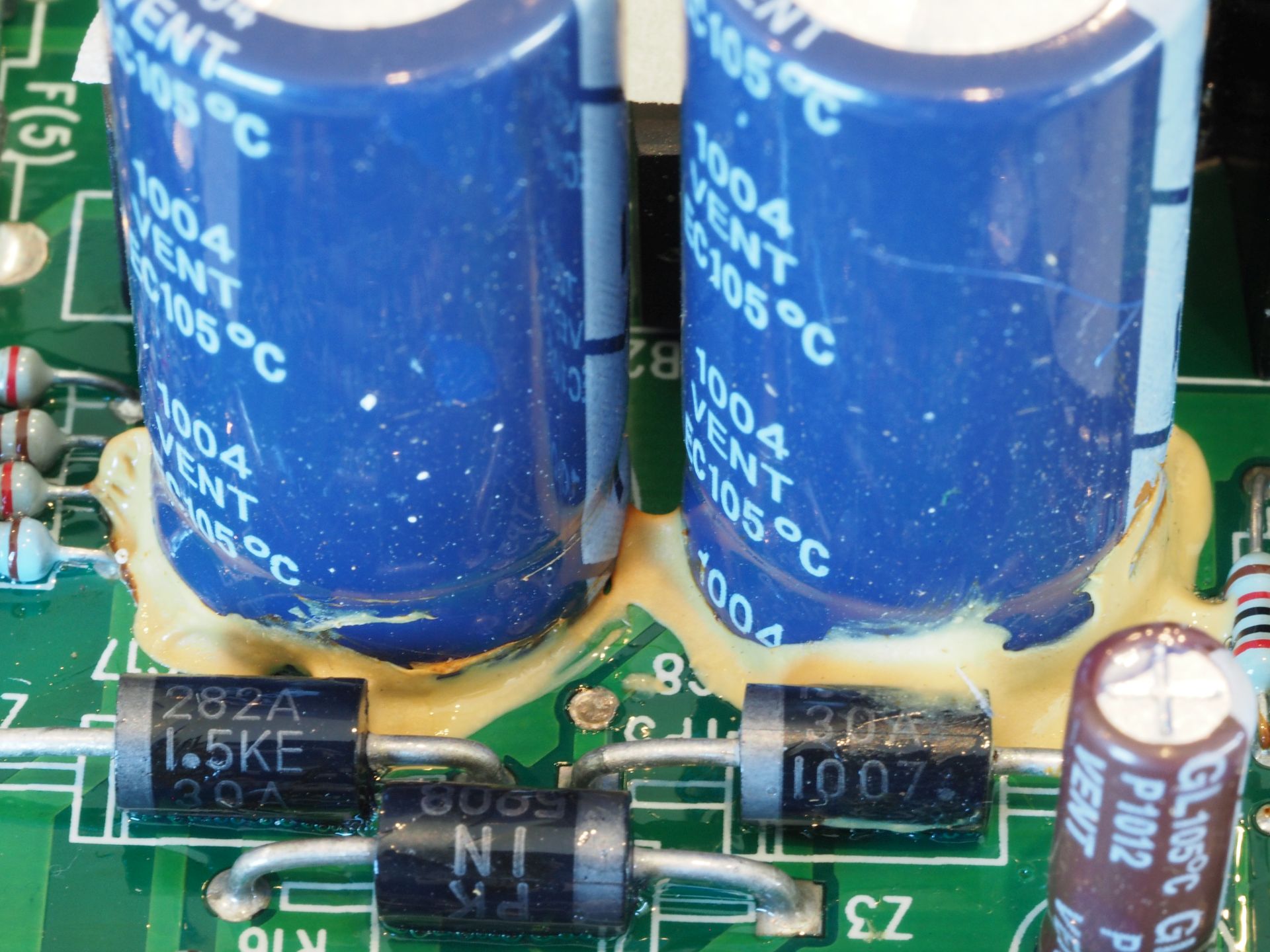

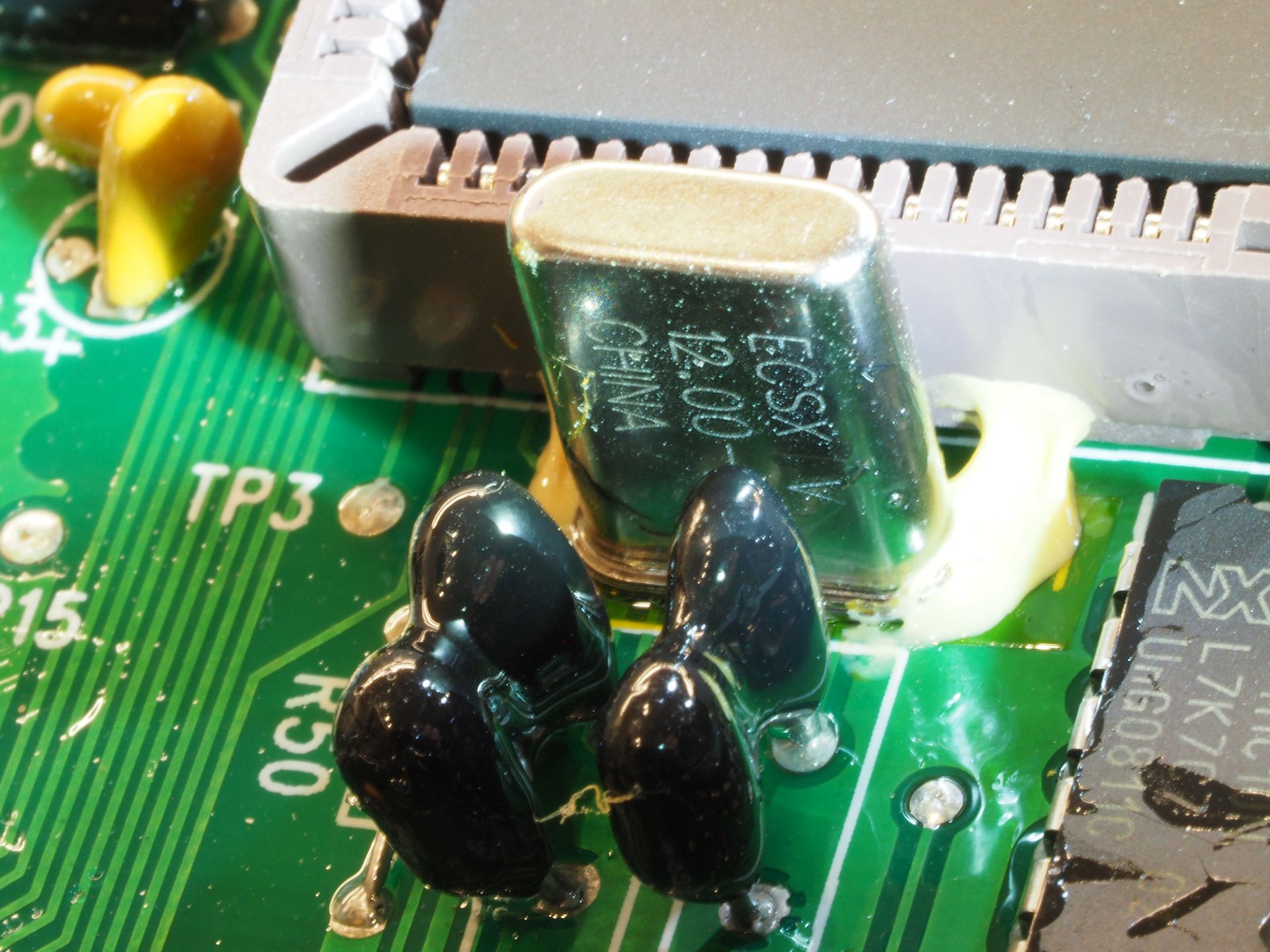

Hi, I am new to this forum and I make no pretence to know my way around small electrons (as opposed to the big ones that drive conveyors and crushers!!!) Hoping someone might be able to provide me some guidance. I bought a second hand spa (2010 Sundance Optima) and installed it two months ago. It ran fine until last week then the controller display started flickering. Usually switching the power off and on again a minute or so later got her running again, however two days ago i got a frozen display (what Sundance call the dreaded Watchdog error and their recommendation is to call one of their service techs and open your wallet up wide!!!) and have lost all ability to operate the spa. I opened her up and checked that there was power to the control board, removed and checked all fuses, checked all terminations/junctions were clean and tight, checked transformer output and checked the back of board for dry solder joints and having no luck, then got on the internet. Apparently these boards are prone to capacitor failure. Attached photo 669 shows overall board and 668 shows the six round caps and what i think might be a (failed?) crystal which i will come to. Caps C8 and C17 (which i have subsequently removed) are 3300uF 35V and show a yellowish brittle non-conductive gunk around their bases. The top of these two caps appears flat. C5 and C58 are 10uF 50V and C33 and C57 are 150uF 35V and these four at least visually look ok. There is also a silver device shown in photo 680 which i assume is a crystal and it too has a similar yellowish brittle gunk around its base. It is labelled ECSX/V, 12.00 - 20, china. I do not have the ability to test these caps or crystal. My questions are:

1) is the yellow gunk a fair indication of shot caps and a shot crystal?

2) if C8 and C17 are shot i'm guessing it would be sensible to replace all caps?

3) should a crystal leak this yellow gunk?

4) I've tried to find this crystal as a replacement part on the web and i can't get an exact match with the coding on it. Can someone distill this coding down to something i can order please (Sundance don't appear to sell this as a spare part)

5) Is this yellow gunk likely to do any damage to other components that it touches?

6) what is the mode of leaking this gunk? I'm guessing it fluidises when its warm or hot and solidifies when it is cold?

Many thanks in advance for your assistance!!

1) is the yellow gunk a fair indication of shot caps and a shot crystal?

2) if C8 and C17 are shot i'm guessing it would be sensible to replace all caps?

3) should a crystal leak this yellow gunk?

4) I've tried to find this crystal as a replacement part on the web and i can't get an exact match with the coding on it. Can someone distill this coding down to something i can order please (Sundance don't appear to sell this as a spare part)

5) Is this yellow gunk likely to do any damage to other components that it touches?

6) what is the mode of leaking this gunk? I'm guessing it fluidises when its warm or hot and solidifies when it is cold?

Many thanks in advance for your assistance!!