fingaz

Member

Hi,

I have just brought a motorbike, which has been 'modified' by removing the fairing. Only problem is that the guy who removed the fairing has also got rid of some of the electrics.

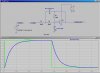

Basically, the bike has no fuel gauge. It has the sensor, and wiring. The original fuel level sensor works by varying the resistance depending on the level of fuel. According to the specs, it should read between 4 to 10 ohms when full, and between 90 to 100 ohms when empty.

I basically want to make some kind of 'gauge', though all it needs to do really is show when the tank is full, half full, and empty. I can't just stick the original gauge back on because I'm restricted to space. If I can make something, i can make it fit the space I have.

Can anyone make suggestions as to how I could do this? PIC's are not really an option unless someone already has the 'software/code' (I have a pic programmer, but am not experienced at all with writing code)

All suggestions are welcome, any help would be gratefully received.

Thanks

I have just brought a motorbike, which has been 'modified' by removing the fairing. Only problem is that the guy who removed the fairing has also got rid of some of the electrics.

Basically, the bike has no fuel gauge. It has the sensor, and wiring. The original fuel level sensor works by varying the resistance depending on the level of fuel. According to the specs, it should read between 4 to 10 ohms when full, and between 90 to 100 ohms when empty.

I basically want to make some kind of 'gauge', though all it needs to do really is show when the tank is full, half full, and empty. I can't just stick the original gauge back on because I'm restricted to space. If I can make something, i can make it fit the space I have.

Can anyone make suggestions as to how I could do this? PIC's are not really an option unless someone already has the 'software/code' (I have a pic programmer, but am not experienced at all with writing code)

All suggestions are welcome, any help would be gratefully received.

Thanks

Last edited: