g2c

Member

Hello to everyone,

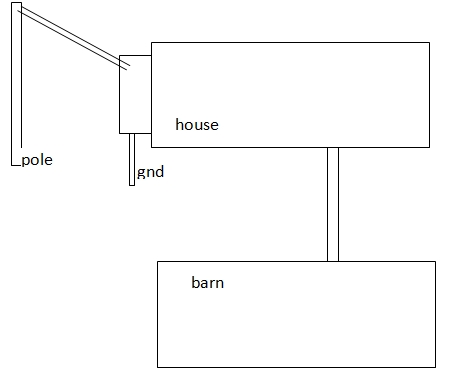

This is about electricity practice

In my home I have a ground rod which 'distributes' ground to my outlets.

The two phases coming from the pole goes to the counter (one through a physical 63A fuse)

then the phases go to a differential line breaker (one through a thermal 40A breaker) and are distributed to the house loads and outlets via breakers

One of the loads is a barn situated 30m from the house, connected with a cable made of 3 1.5mm^2 wires. The cable is plugged to an external wall plug.

Now I want to replace this cable by a permanent connection so I dug a .5m deep tunnel in which I burried a 7cm tube and I intend to run though the tube power (2.5mm^2 wires) and signaling/telecom.

My questions:

1) where should I connect these power wires? a) after the house differential breaker or b) directly after the counter with a new differential breaker at the barn?

2) Where should I take the ground from? a) the house ground? b) a new ground rod at the barn? in this later case I'd only need to run two 2.5mm^2 wires

Thanks a lot for your time!

This is about electricity practice

In my home I have a ground rod which 'distributes' ground to my outlets.

The two phases coming from the pole goes to the counter (one through a physical 63A fuse)

then the phases go to a differential line breaker (one through a thermal 40A breaker) and are distributed to the house loads and outlets via breakers

One of the loads is a barn situated 30m from the house, connected with a cable made of 3 1.5mm^2 wires. The cable is plugged to an external wall plug.

Now I want to replace this cable by a permanent connection so I dug a .5m deep tunnel in which I burried a 7cm tube and I intend to run though the tube power (2.5mm^2 wires) and signaling/telecom.

My questions:

1) where should I connect these power wires? a) after the house differential breaker or b) directly after the counter with a new differential breaker at the barn?

2) Where should I take the ground from? a) the house ground? b) a new ground rod at the barn? in this later case I'd only need to run two 2.5mm^2 wires

Thanks a lot for your time!