hoshimi_takara

New Member

I am hoping one of you guys can help a mechanical engineer who is stretching her skill.

You all seem to have much knowledge and like to help and share.

I have been given a brushed drill motor which physically fits my project perfectly but I need help with connections.

It was made for volt 220/240 50cycle.

I only need it run full speed in one direction.

I have been told the original tool had a trigger which included a speed control and capacitor and it had electronic torque control.

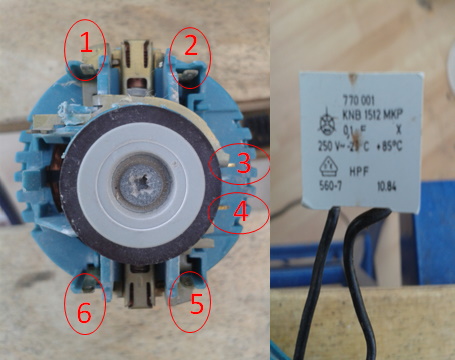

I only have the motor and capacitor - see photo. The motor has six connections - I have number the terminals 1 to 6.

Number 2 & 5 are for brushes. An ohm meter finds 1 & 4 plus 3 & 6 are pairs.

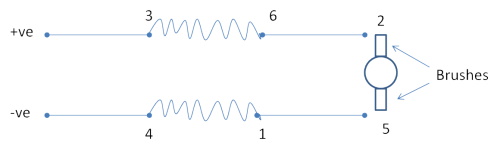

I have drawn what I think the connections could be but I am not brave enough to try without help.

If I spin wrong way do I reverse +ve & -ve?

I have no clue which terminals would connect the capacitor.

Thanking in advance

You all seem to have much knowledge and like to help and share.

I have been given a brushed drill motor which physically fits my project perfectly but I need help with connections.

It was made for volt 220/240 50cycle.

I only need it run full speed in one direction.

I have been told the original tool had a trigger which included a speed control and capacitor and it had electronic torque control.

I only have the motor and capacitor - see photo. The motor has six connections - I have number the terminals 1 to 6.

Number 2 & 5 are for brushes. An ohm meter finds 1 & 4 plus 3 & 6 are pairs.

I have drawn what I think the connections could be but I am not brave enough to try without help.

If I spin wrong way do I reverse +ve & -ve?

I have no clue which terminals would connect the capacitor.

Thanking in advance