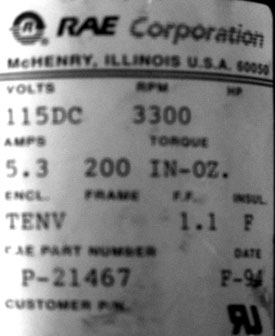

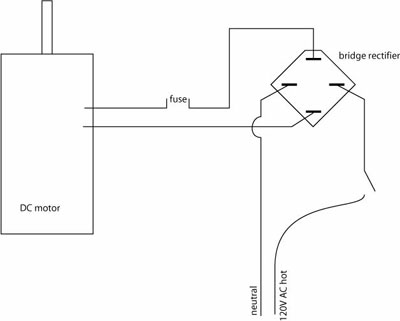

Hi, I have a DC motor that I want to make a variable speed controller for. The motor is a 115 volt, 3300 RPM, 5.3 amp, permanent magnet, brushed motor. I have it hooked up to 120 volt AC through a bridge rectifier, which seems to work well, I just need to get a variable speed control hooked up to it, as I am using it to drive a potter’s wheel. I tried a variable speed controller that I bought from Grizzly, but it didn’t work, probably because it is made for routers which are universal motors (?) and not the same as the motor I am working with. I’m not well versed in electronics, but can build to plans. Anyone have any ideas?