Athosworld

Member

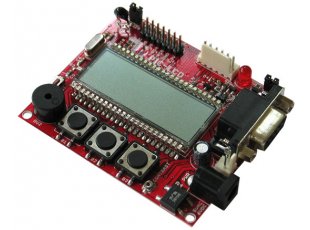

I want to control a bare dot matrix display with an ATMega328p but I have no experience on doing this, what code do I need to create a “wiggle” AC signal to drive that LCD? Or do I have a driver IC between the ATMega and the LCD?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Yes, definitely.Or do I have a driver IC between the ATMega and the LCD?

Nice findAttached are two AVR application notes (doc2569 and doc8103) about driving LCDs with general purpose I/O. (The ATMEGA328 is an AVR controller.)

Can you post a picture of said dot matrix... It looks like others have assumed some type of LCD..

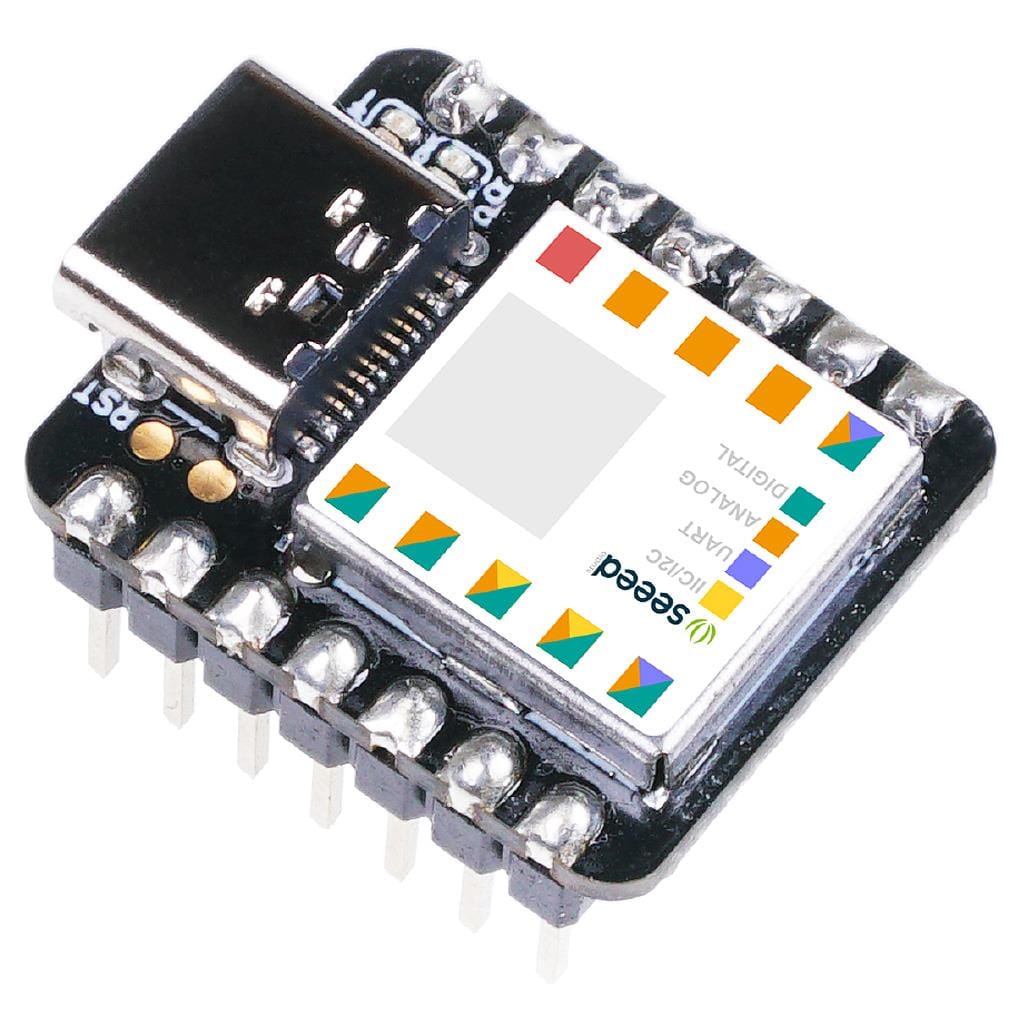

Is this a simple 8 x 8 led matrix?? If not, then a driver would make it easier.

AC signal to drive that LCD

Im not “crazy”, just trying to learn to make something like that.Following on from his previous crazy posts it seems fairly obvious he's expecting to make a low cost COB system,

To the above, I would add: The AVR controllers are pretty expensive, plus I don't particularly like the idea of shipping controllers with flash memory because they tend to stop working after a while. This is less of a problem with automotive grade chips but it still exists as a potential source problems.

The ATMEGA48/88/168/328 family is a great tool for feeling your way around a new subject, and to a certain extent the Arduino platform would make life a lot easier than learning yet another assembly lanugage but if you really anticipate high volume production you would be best off because of cost and potentially reliability considering an IC designed specifically designed to perform this function. To wit: https://www.nxp.com/products/peripherals-and-logic/lcd-drivers:MC_71118

To the above, I would add: The AVR controllers are pretty expensive, plus I don't particularly like the idea of shipping controllers with flash memory because they tend to stop working after a while.

I've ever seen any issues with PIC's, perhaps it's a failing of the Atmel parts?.I am only reporting my philosophy and experience.

I have been using AVR controllers since 2002 and already I have found several projects that stopped working because the flash memory got flaky just sitting on the shelf most of the time. Most of those were programmed with Atmel's AVRISP or STK-500.

I am now worried about a piece of test equipment on the market that the client started making and selling in 2016. That used the ATMEGA48 automotive temperature range part so I'm hoping they last longer than earlier parts.

My main point is that a special purpose chip will probably be less expensive and more reliable than an ATMEGA controller.

I am only reporting my philosophy and experience.

I have been using AVR controllers since 2002 and already I have found several projects that stopped working because the flash memory got flaky just sitting on the shelf most of the time. Most of those were programmed with Atmel's AVRISP or STK-500.

I am now worried about a piece of test equipment on the market that the client started making and selling in 2016. That used the ATMEGA48 automotive temperature range part so I'm hoping they last longer than earlier parts.

My main point is that a special purpose chip will probably be less expensive and more reliable than an ATMEGA controller.