Hello,

First of all, please apologize for the potentials language issues, English is not my native language but I'll do my best

For a little project, I'm trying to control the speed of a sewing machine with an Arduino but I can't make it work...

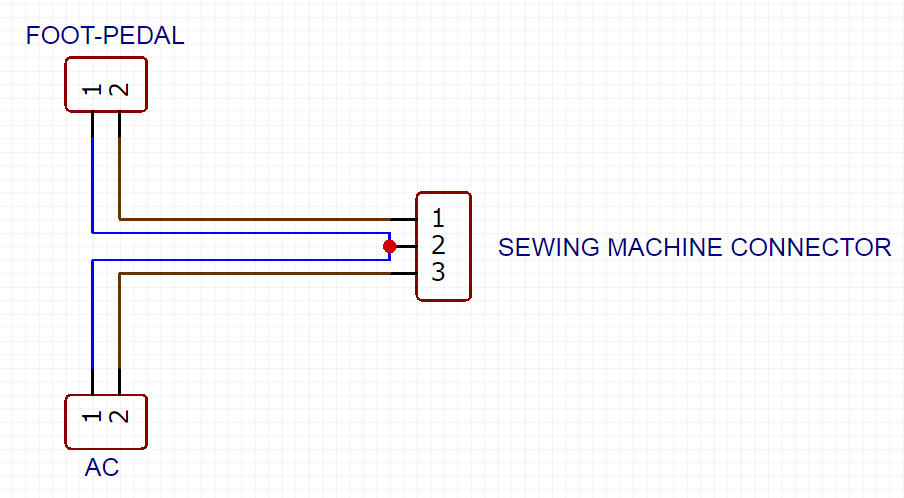

The first thing I did was to try to undestand the wiring of the connector with a multimeter and this is what I found :

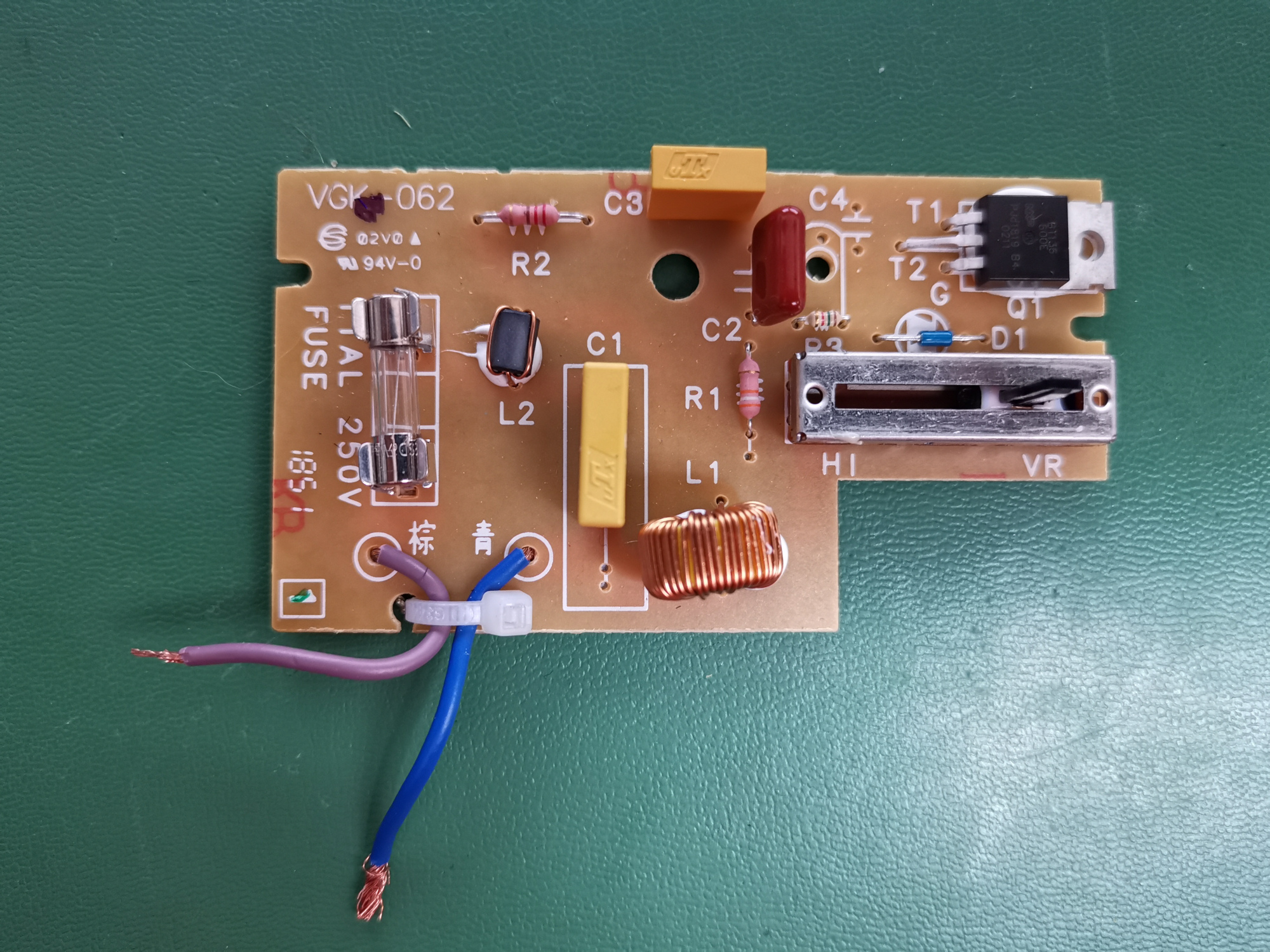

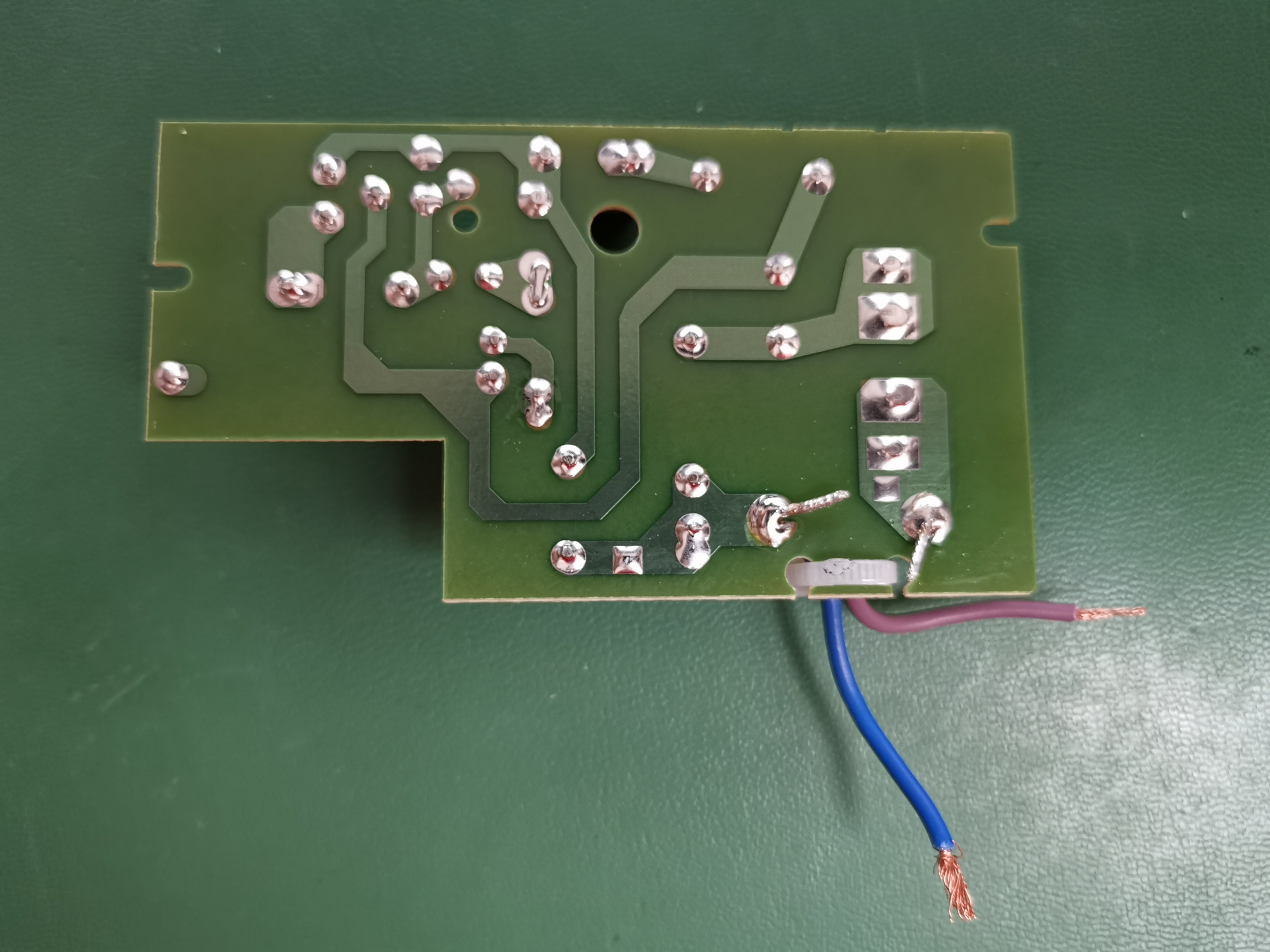

After that, I opened the foot pedal to know how the speed was controlled and here it is :

I'm a software developper and this circuit is far beyond my electronics knowledge so I googled the ref of the top right corner component (BT136) and I've found some topics about TRIAC dimmers and, correct me if I'm wrong, this is what this circuit is, right ?

The next step was to find a TRIAC dimmer controllable with an Arduino and I found this one : https://robotdyn.com/ac-light-dimmer-module-1-channel-3-3v-5v-logic-ac-50-60hz-220v-110v.html

I've tried a lot of different wiring with this module but I've not been able to get descent results : I cannot find a way to get a linear output voltage between 38 and 220V like the one produced by the foot pedal...

So here are my questions : Is the dimmer module I bought what I really need to replace the foot pedal of my sewing machine ? If not, is it even possible to control with an Arduino the speed of my sewing machine ?

If you need more details, please ask

Thanks,

Yoann

First of all, please apologize for the potentials language issues, English is not my native language but I'll do my best

For a little project, I'm trying to control the speed of a sewing machine with an Arduino but I can't make it work...

The first thing I did was to try to undestand the wiring of the connector with a multimeter and this is what I found :

After that, I opened the foot pedal to know how the speed was controlled and here it is :

I'm a software developper and this circuit is far beyond my electronics knowledge so I googled the ref of the top right corner component (BT136) and I've found some topics about TRIAC dimmers and, correct me if I'm wrong, this is what this circuit is, right ?

The next step was to find a TRIAC dimmer controllable with an Arduino and I found this one : https://robotdyn.com/ac-light-dimmer-module-1-channel-3-3v-5v-logic-ac-50-60hz-220v-110v.html

I've tried a lot of different wiring with this module but I've not been able to get descent results : I cannot find a way to get a linear output voltage between 38 and 220V like the one produced by the foot pedal...

So here are my questions : Is the dimmer module I bought what I really need to replace the foot pedal of my sewing machine ? If not, is it even possible to control with an Arduino the speed of my sewing machine ?

If you need more details, please ask

Thanks,

Yoann