Grr,

I have a circuit I'd like to get made on to some PCBs and I can't find any low-cost places I can get it made up properly in the UK, so I'm going to have to try and etch it myself using either a steady hand or some sort of press-n-peel.

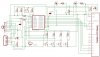

The schematic is attached and as you can see its quite compled. The main bits are the PICAXE and the LCD. Also a 6 way header and an ethernet socket.

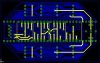

Anyone here think that it's possible to get that done on two single side copper boards, 65x65mm max? If so what do you suggest for layout the best? I will use ribbon cable to connect the two boards. The top one needs to have 16 pins at 2.54mm spacing along the bottom-left edge somewhere for the LCD (14 pins + 2 for the backlight - shown by LED1 on the diagram).

Any tips are welcomed. Many autorouter tools fail to manage to route it!

I have a circuit I'd like to get made on to some PCBs and I can't find any low-cost places I can get it made up properly in the UK, so I'm going to have to try and etch it myself using either a steady hand or some sort of press-n-peel.

The schematic is attached and as you can see its quite compled. The main bits are the PICAXE and the LCD. Also a 6 way header and an ethernet socket.

Anyone here think that it's possible to get that done on two single side copper boards, 65x65mm max? If so what do you suggest for layout the best? I will use ribbon cable to connect the two boards. The top one needs to have 16 pins at 2.54mm spacing along the bottom-left edge somewhere for the LCD (14 pins + 2 for the backlight - shown by LED1 on the diagram).

Any tips are welcomed. Many autorouter tools fail to manage to route it!