Thunderchild

New Member

So I'm charging up a car battery with 2 solar panels (max 2.25 amps output from both)

now as far as I know at 14.5 volts 15 max the battery is charged, is this the voltage across the battery whilst under charge or when the charging powerr is disconected ? meaning do i have to disconect the panels and after a few seconds check the battery voltage or can I check it whilst under charge ?

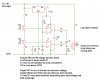

if I were to charge the battery from a 14.5 volt regulator would this prevent the battery from overcharging ?

now as far as I know at 14.5 volts 15 max the battery is charged, is this the voltage across the battery whilst under charge or when the charging powerr is disconected ? meaning do i have to disconect the panels and after a few seconds check the battery voltage or can I check it whilst under charge ?

if I were to charge the battery from a 14.5 volt regulator would this prevent the battery from overcharging ?