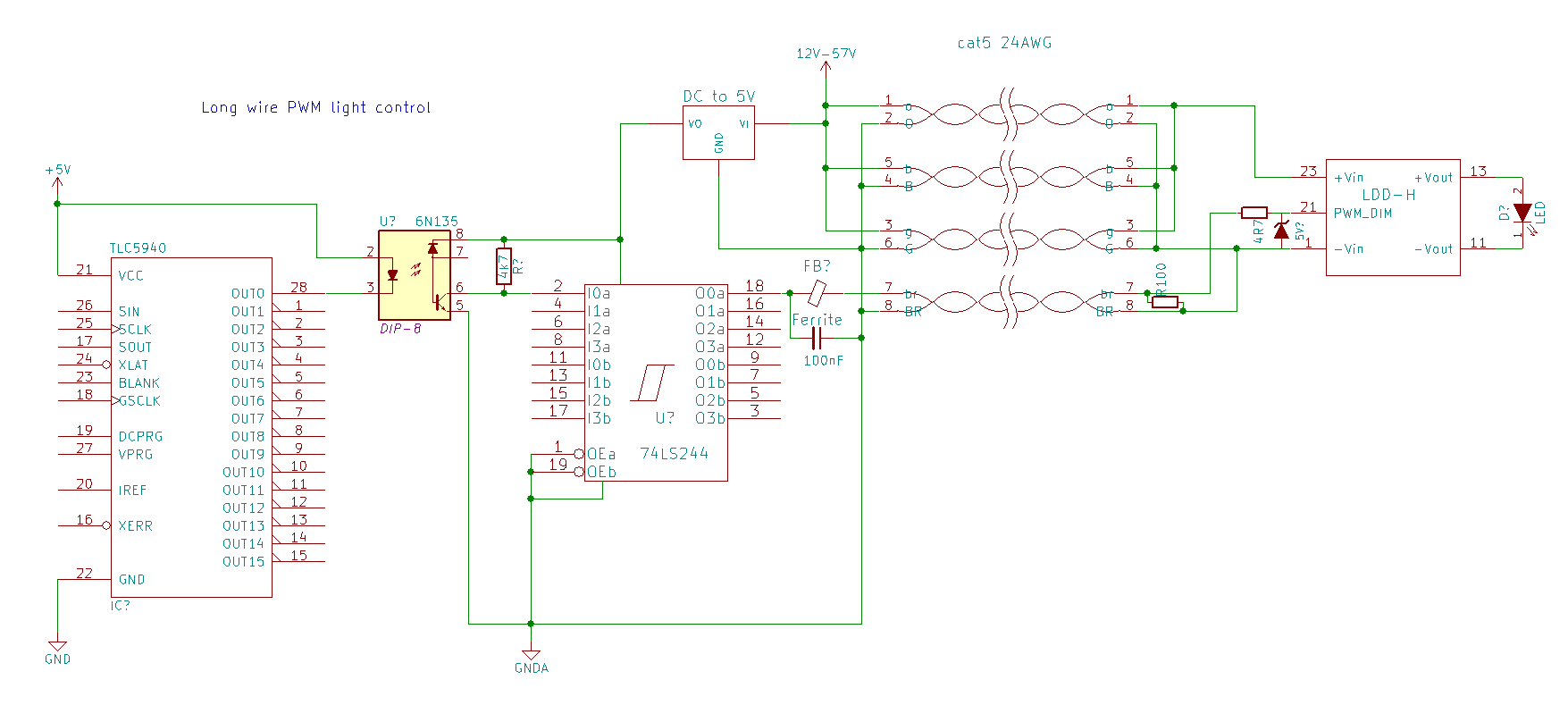

Hey guys, I am trying to design a circuit for PWM control of ceiling downlights with a microconroller. Here's a schema I came up with so far:

TLC5940 is controlled by a microcontroller (not shown). It's output is connected to a logic optocoupler (6N135 or similar) whose output is connected to a line driver (74244 or similar). The output of the line driver goes through a ferrite bead and connected to a capacitor to reduce EMI. The 5V PWM signal from the line driver then travels through one pair of cat5 cable (estimating 10m at max) which is terminated at the end with a 100 ohm (+-15ohm) resistor to reduce reflections. It then continues through a 4R7 resistor to the PWM input of a constant current driver (like for example LDD-350H). The PWM input has a 5V1 zener diode on its input to clamp any excess voltage. The other pairs of the cat5 cable are used to carry anything between 12V and 57V depending on the downlight (and appropriate current driver) requirements. The line driver is powered by a DC to 5V module.

The PWM signal on the remote side does not have to be perfect, I don't think it will cause too much variance in brightness (as oppose to a perfect PWM signal). LED downlights won't need more than 700mA. Most of those I looked at are 350mA or 500mA. But the voltage can be quite different depending on the chosen downlight (number of LEDs, technology,...).

So my question is whether this design is any good and what would you improve? Especially in terms of reliability, safety and coexistence with other electronic devices in the house. Here is a few notes and questions:

1. I'd like to keep the remote/light side as simple as possible but I can add as many passive components as needed if it improves any of the three things I mentioned earlier. Maybe add another 5V TVS diodes on both sides to protect against surges? And another TVS diodes on the power lines? I can also add any active and passive components on the side of the line driver.

2. Those cat5 cables are going to create a star like topology on the ceiling (imagine 20 lights) and with those long wires I am bit worried about EMI. Is the cat5 twisted cable going to mitigate EMI to acceptable levels? I can use a shielded cat5 if necessary.

3. If there will be any power lines (230V) crossing those wires e.g. for controlling electrical jalousies, will switching 230V cause the lights to flicker (even for a brief moment)? If so, how to prevent it? Better shielding or some filters? Maybe another 100nF capacitor on the PWM input?

4. Is the line driver necessary? Would the optocoupler be enough to drive the PWM line? I will rather keep the line driver if it's better to use it, I do not want to be changing that optocoupler every month.

5. Anything else I should be thinking of?

TLC5940 is controlled by a microcontroller (not shown). It's output is connected to a logic optocoupler (6N135 or similar) whose output is connected to a line driver (74244 or similar). The output of the line driver goes through a ferrite bead and connected to a capacitor to reduce EMI. The 5V PWM signal from the line driver then travels through one pair of cat5 cable (estimating 10m at max) which is terminated at the end with a 100 ohm (+-15ohm) resistor to reduce reflections. It then continues through a 4R7 resistor to the PWM input of a constant current driver (like for example LDD-350H). The PWM input has a 5V1 zener diode on its input to clamp any excess voltage. The other pairs of the cat5 cable are used to carry anything between 12V and 57V depending on the downlight (and appropriate current driver) requirements. The line driver is powered by a DC to 5V module.

The PWM signal on the remote side does not have to be perfect, I don't think it will cause too much variance in brightness (as oppose to a perfect PWM signal). LED downlights won't need more than 700mA. Most of those I looked at are 350mA or 500mA. But the voltage can be quite different depending on the chosen downlight (number of LEDs, technology,...).

So my question is whether this design is any good and what would you improve? Especially in terms of reliability, safety and coexistence with other electronic devices in the house. Here is a few notes and questions:

1. I'd like to keep the remote/light side as simple as possible but I can add as many passive components as needed if it improves any of the three things I mentioned earlier. Maybe add another 5V TVS diodes on both sides to protect against surges? And another TVS diodes on the power lines? I can also add any active and passive components on the side of the line driver.

2. Those cat5 cables are going to create a star like topology on the ceiling (imagine 20 lights) and with those long wires I am bit worried about EMI. Is the cat5 twisted cable going to mitigate EMI to acceptable levels? I can use a shielded cat5 if necessary.

3. If there will be any power lines (230V) crossing those wires e.g. for controlling electrical jalousies, will switching 230V cause the lights to flicker (even for a brief moment)? If so, how to prevent it? Better shielding or some filters? Maybe another 100nF capacitor on the PWM input?

4. Is the line driver necessary? Would the optocoupler be enough to drive the PWM line? I will rather keep the line driver if it's better to use it, I do not want to be changing that optocoupler every month.

5. Anything else I should be thinking of?