Bob Scott

New Member

Automobile ignition systems used to use points and a capacitor, known as a "condenser" in wrenchhead-speak. We electronics types stopped using the word "condenser" back in the '60s.

The inductance of the ignition coil primary winding and the capacitor form a tuned circuit. Does anyone know, offhand, what the value of the "condenser" is in uF? Also the typical inductance of the coil's primary winding?

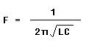

I'd like to calculate the resonant frequency using the equation f = 1 / (2*pi*(L*C)^0.5).

I think that the period of oscillation causes a spark delay and is compensated for by using the vacuum advance.

The inductance of the ignition coil primary winding and the capacitor form a tuned circuit. Does anyone know, offhand, what the value of the "condenser" is in uF? Also the typical inductance of the coil's primary winding?

I'd like to calculate the resonant frequency using the equation f = 1 / (2*pi*(L*C)^0.5).

I think that the period of oscillation causes a spark delay and is compensated for by using the vacuum advance.

Last edited: