hi guys, this is my first post (love the forum, tons of people here willing to help out - BRILLIANT!!). now, i need to be treated as a novice, because i am one!

THE PRODUCT: 4 LED lamp powered by AAA batteries.

THE DESIGN: 100x100x15mm unit with one LED in the middle of each 100mm side (4 sides = 4 LEDs). power source will be housed in the center of the unit, 15mm height is just enough to accommodate diameter of AAA battery plus the battery holder.

THE ISSUE(S): the minimum voltage range of the LED is 3.0V, typical is 3.4V and max is 3.8V. 3x AAA battery holders are very rare, 2x and 4x AAA holders are more available and affordable (for mass producing the product!). 2x AAA would mean the LEDs would be at optimum-ish luminosity for only a few minutes before the voltage starts to drop and they start to dim. 4x AAA exceeds the max rating of the LEDs, and even if they worked, it would drastically reduce the lifespan of the LEDs.

i'm planning on placing the LEDs in a parallel circuit (i seem to have a misconception that parallel circuits are generally more efficient than series) and stick a resistor in to reduce the voltage but i have no idea what resistance these LEDs are and what the total resistance would be of 4 of them in parallel. also, i'm wondering about the power wastage of it all. the LEDs in series would be much easier, construction-wise but not sure if 6V from the 4x AAA power source is sufficient.

THE GOAL: to create the simplest and most energy efficient circuit to power 4 LEDs using either a 3V or 6V power source, giving the product it's maximum running time!

OTHER ISSUES: current - i know the LEDs are probably anywhere from 30mA to 80mA each but really don't know what current is generated from these banks of Duracell cells! mA hours - the Duracell pack doesn't say what their's is (unlike rechargeable ones), so i don't know how to calculate what the units max continuous usage time would be.

fellas, i know this is pretty beneath you but i thank you all in advance for all your help. thanks!

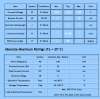

p.s. attached is the spec sheet of the LEDs. if not, then you can view them here: **broken link removed**

THE PRODUCT: 4 LED lamp powered by AAA batteries.

THE DESIGN: 100x100x15mm unit with one LED in the middle of each 100mm side (4 sides = 4 LEDs). power source will be housed in the center of the unit, 15mm height is just enough to accommodate diameter of AAA battery plus the battery holder.

THE ISSUE(S): the minimum voltage range of the LED is 3.0V, typical is 3.4V and max is 3.8V. 3x AAA battery holders are very rare, 2x and 4x AAA holders are more available and affordable (for mass producing the product!). 2x AAA would mean the LEDs would be at optimum-ish luminosity for only a few minutes before the voltage starts to drop and they start to dim. 4x AAA exceeds the max rating of the LEDs, and even if they worked, it would drastically reduce the lifespan of the LEDs.

i'm planning on placing the LEDs in a parallel circuit (i seem to have a misconception that parallel circuits are generally more efficient than series) and stick a resistor in to reduce the voltage but i have no idea what resistance these LEDs are and what the total resistance would be of 4 of them in parallel. also, i'm wondering about the power wastage of it all. the LEDs in series would be much easier, construction-wise but not sure if 6V from the 4x AAA power source is sufficient.

THE GOAL: to create the simplest and most energy efficient circuit to power 4 LEDs using either a 3V or 6V power source, giving the product it's maximum running time!

OTHER ISSUES: current - i know the LEDs are probably anywhere from 30mA to 80mA each but really don't know what current is generated from these banks of Duracell cells! mA hours - the Duracell pack doesn't say what their's is (unlike rechargeable ones), so i don't know how to calculate what the units max continuous usage time would be.

fellas, i know this is pretty beneath you but i thank you all in advance for all your help. thanks!

p.s. attached is the spec sheet of the LEDs. if not, then you can view them here: **broken link removed**